Hey everyone, I'm planning to throw together a cheap and easy plywood pram, probably in the 8 foot(ish) range. This is going to be a utility boat used exclusively for solo duck hunting and nearshore fishing. It will likely never see deep water. I want it to be small and light so a regular car can pull it, or roof rack it. And I need to be able to handle moving it around by myself. I also want to keep it affordable as this isn't meant to be a pleasure craft; just something to get the job done.

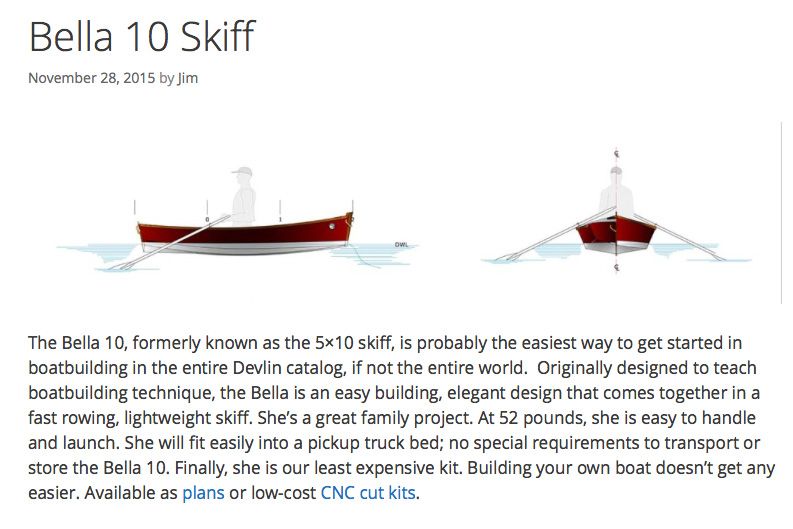

I am thinking something similar to this, without the sail rig:

sprite-2-w730.jpg

I am able to get some high grade baltic birch ply that is alleged to have no voids. If that doesn't look up to snuff I will use meranti BS1088. Okoume is double the price of the meranti at my local supplier and that's too expensive.

My question to everyone is: for a boat like this that is basically built from 2 sheets of ply, do I need to glass and epoxy the thing or are there alternatives? I know that this will be the most durable, long term solution. However cost and weight are both factors here. I'm hoping for cheaper, easier solutions, but am open to glassing it if I have to.

Reply With Quote

Reply With Quote