Our two Boys are in their early/mid 20’s and are avid hunters/shooters. For Christmas I built them both simple rifle cases out of what the local BORG called “whitewood”.

I wanted something light, hand tool friendly and situationally appropriate/cost-effective given these cases are likely to be banged on/off airplanes, trucks and generally treated the way young men treat most things.

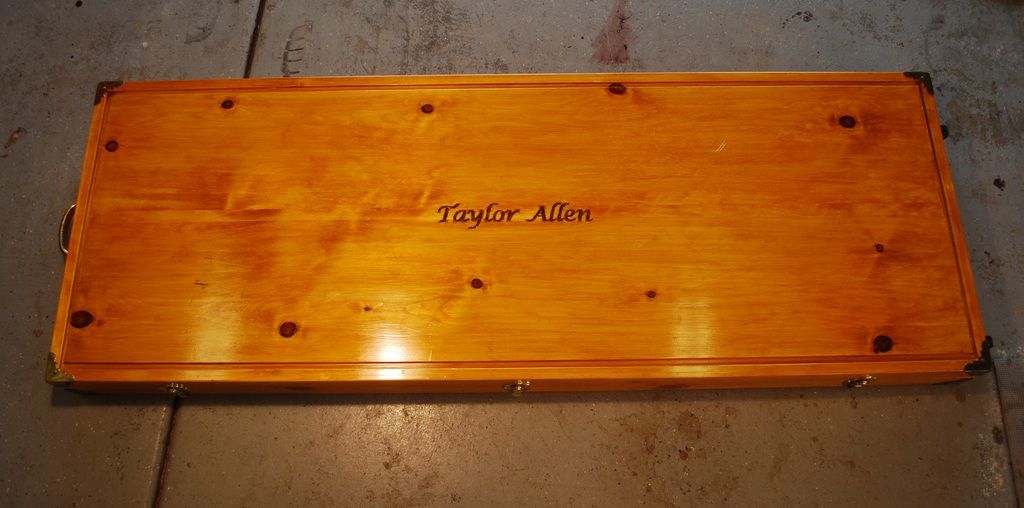

Here are a couple pictures of the case for our oldest: ~ 60” L x 20” W X 4” T, intended to hold two, small caliber rifles. It’s a simple box – vertical members dovetail at the corners, solid wood frame and panel for the top and bottom. For added strength, there are 4” wide pieces under the panels that go across the case.

\

I glued up the box and then sawed the lid from the case with a rip saw. Brass hinges, latches and corner reinforcement plates with simple paracord stays. I’m still waiting on the case locks and handles. Finish is Amber shellac covered with marine spar varnish.

By far the hardest part of the build was the foam for French fitting, which is my primary reason for posting.

First a disclaimer – I think French fitting is cool! I’ll admit it; my pulse rate bumps a little every time I click the latches and opened a box that holds something nestled in French fitting. For me, this signifies “you definitely didn’t get this from IKEA”, and whatever’s inside is usually something special. That’s what I was going for with these rifle cases.

Now that they’re done, I think I may have been “pound wise and penny foolish” and FWIW thought it might be helpful to share my observations with my fellow Neanders whom I have some interest in French fitting.

Foam intended for French fitting is commercially available from weapons case manufacturers like Pelican and a range of other suppliers like Kaizen etc. I’m not very good at sourcing materials from the Internet, but my feeble investigation indicated the cost of foam I needed for 2 rifle cases was around $400, which was significantly more than I expected. For perspective, I don’t recall paying that much for complete, top-of-the-line Zero Halliburton and Pelican cases (including foam), although admittedly mine are probably older than my boys.

In general, I believe “you get what you pay for”, particularly when it comes to tools/firearms, and accordingly am willing to spend a little more. However, I was more than a little surprised/put off by the cost of the options I found online. So in the truest spirit of “I know better, I’m not going to let an industry specific supply chain take advantage of me!” I made the French fitting out of foam from a local craft store.

This was by far the hardest part of the build. I cut the foam with a sharp knife and coping saw and colored it with black paint. I definitely spent waaaay more time on the foam than I did on the woodworking for the cases.

Although the woodworking turned out okay, the foam just didn’t feel right; the surface wasn’t uniform/smooth. Even though it sucked up a ton of paint, I don’t think I got all the cells a uniform color and the color isn’t very durable. As soon as you ding the foam (which is guaranteed moving a weapon in and out of the case), the color is lost.

In summary, I wish I would have spent the money for the best quality material, in this case the French fitting foam. More broadly FWIW, in my 50 years woodworking I’ve never regretted spending more for the best quality material, but have frequently regretted investing the time/effort to build worthwhile projects, without making the same financial commitment to sourcing the best materials.

Just my thoughts, YMMV.

All the best, Mike

Reply With Quote

Reply With Quote