Get out the sand paper, you've got a couple of bad cups. Sand them off and start your trials on them.

Lasers : Trotec Speedy 300 75W, Trotec Speedy 300 80W, Galvo Fiber Laser 20W

Printers : Mimaki UJF-6042 UV Flatbed Printer , HP Designjet L26500 61" Wide Format Latex Printer, Summa S140-T 48" Vinyl Plotter

Router : ShopBot 48" x 96" CNC Router Rotary Engravers : (2) Xenetech XOT 16 x 25 Rotary Engravers

Real name Steve but that name was taken on the forum. Used Middle name. Call me Steve or Scott, doesn't matter.

Reply With Quote

Reply With Quote

)

)

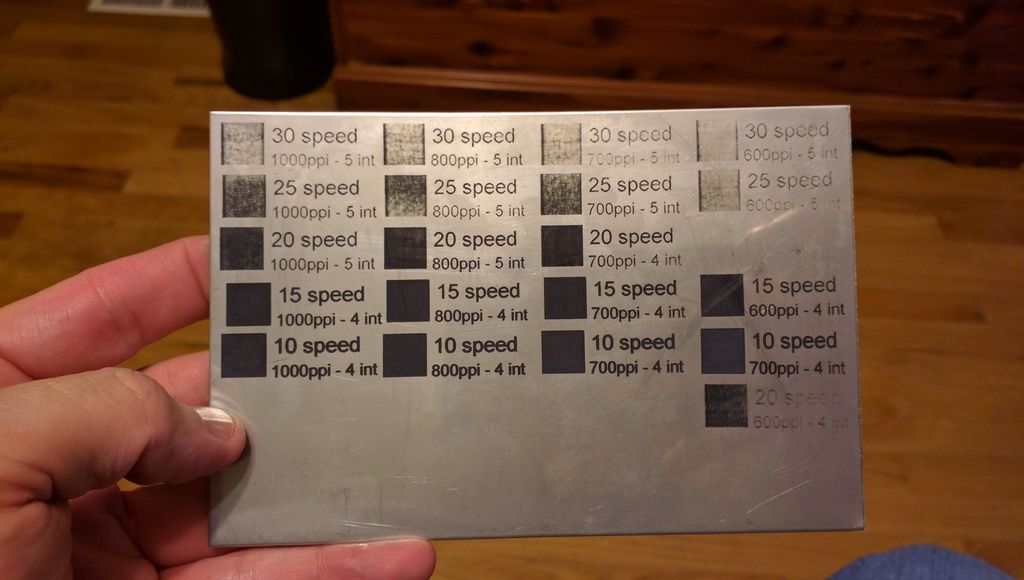

- fiber lasers

- fiber lasers