Just picked up a Veritas 14tpi dovetail saw. This is my first saw that I'm using by hand for "actual" work. I've got a 1x4 pic of select pine in my "vise" on my bench. I cannot get the cut started without pulling the saw back some and making a trench for it to ride in. I'm using paraffin wax on the plate, using a marking knife to make a cut line, holding the saw right...can't figure it out. Once it actually starts going, it seems to cut fine. However, on the "back side" of my cuts, there are fuzzy's like where the saw just pushed material back there? I searched, but didn't know the set of keywords to use to get my response that made sense.

Thanks,

Kevin

Reply With Quote

Reply With Quote

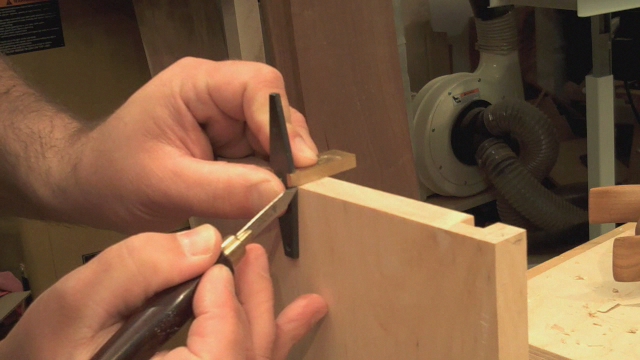

. I work differently, I start the kerf with the toe, make sure everything is alined and then make a light full saw plate cut check the kerf and correct if needed. As always there is no one correct way and YMMV.

. I work differently, I start the kerf with the toe, make sure everything is alined and then make a light full saw plate cut check the kerf and correct if needed. As always there is no one correct way and YMMV.