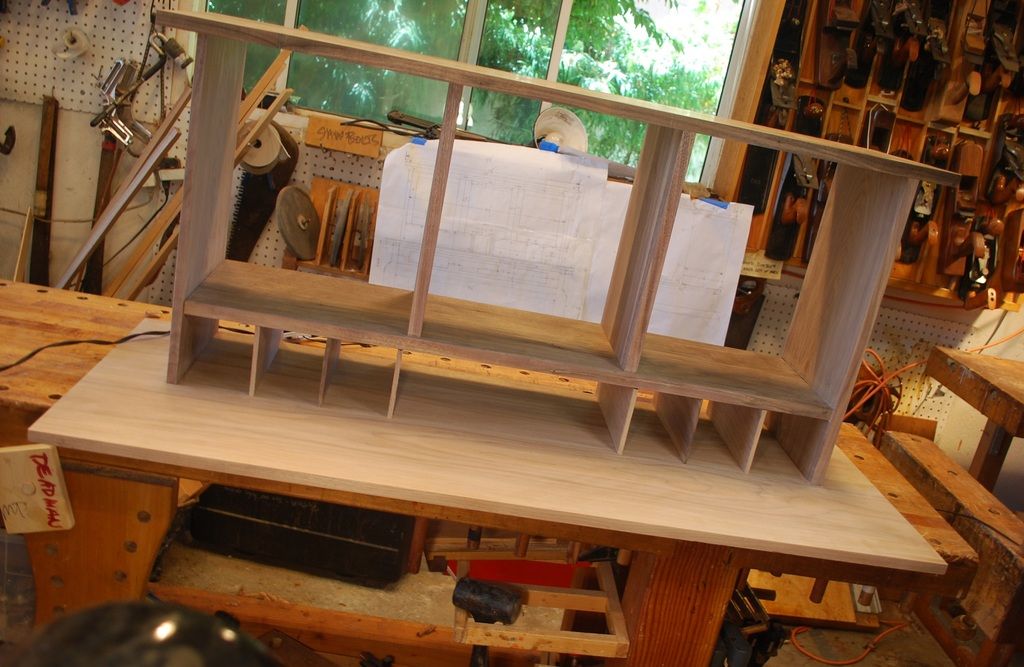

I was motivated to build this project because I like to look through woodworking books to steal ideas when designing a new project. My intent is to build a sort of “desk” with a bookshelf on top that would allow me to pull out books and lay them open to compare various ideas.

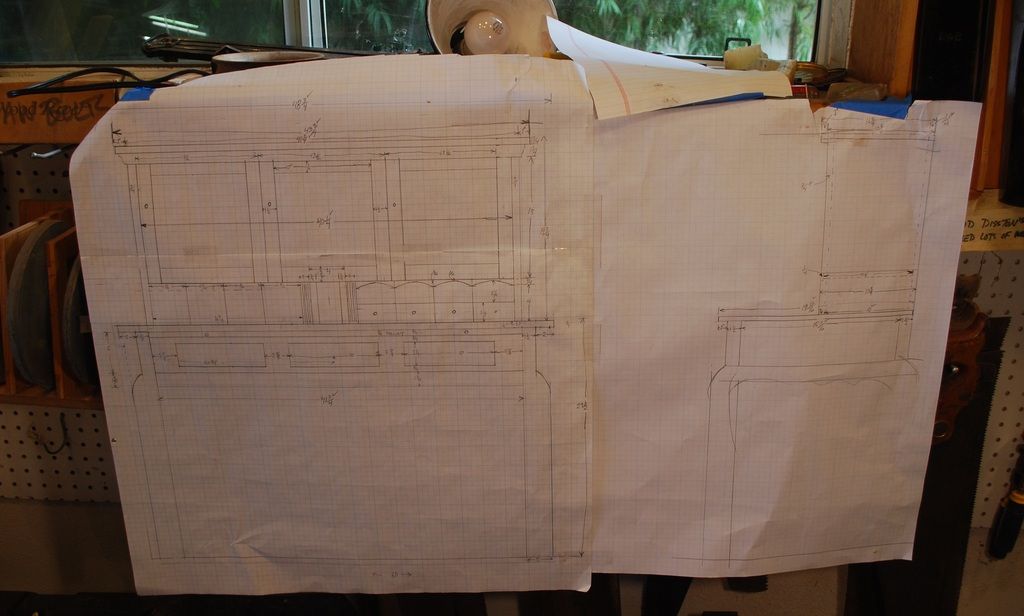

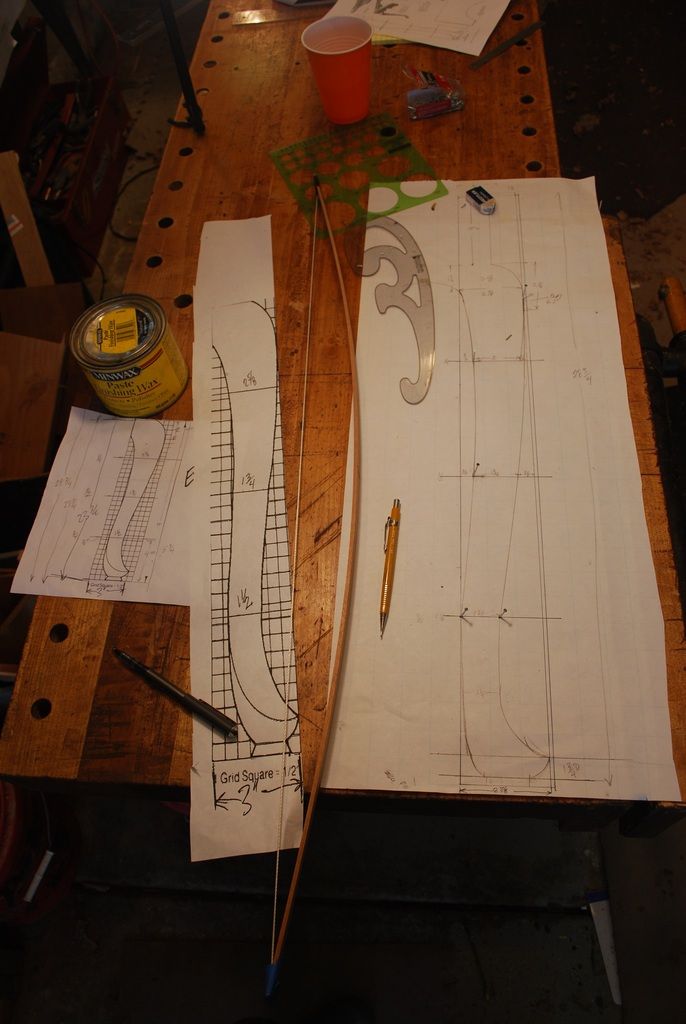

I’m terrible at design. I like to use the biggest graph paper I can find to layout rough dimensions etc. Most will change during the course of the build, but I like having a visual idea of what I’m going for.

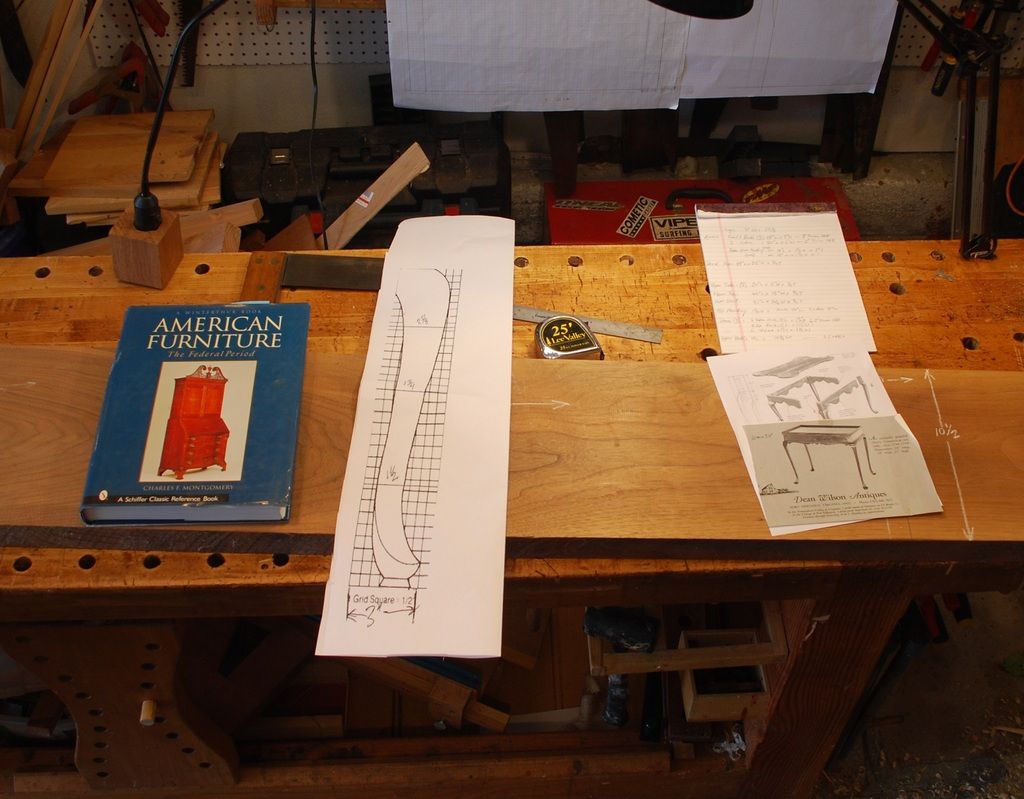

The most difficult part of the design for me is the shape of the Cabriolet legs supporting the desktop. In a perfect world I’d find a template and use a copy machine to expand it to the size I need. Regrettably, that rarely works out proportionally, which requires me to try and design a template on my own.

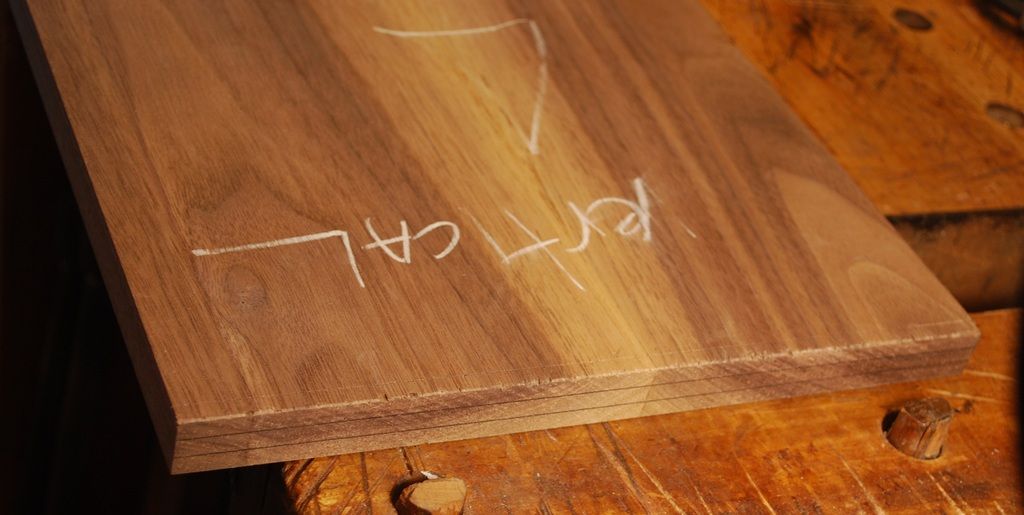

Lumber for this project was waaaay over budget so first step is trying to squeeze as many parts possible out of the available stock in the layout process.

In the hardwood desert of Southern California where I live the best lumber is in the thickest pieces. This is 8/4, 16’ long piece of Walnut that I’m hoping I can squeeze many of the showpieces of the project out of. First step is crosscutting to rough dimension. As a hand tool woodworker, this 5 PPI crosscut D8 is one of my most valuable tools.

When I win the lottery, my first purchase will be a nuclear powered bandsaw with maximum re-saw capacity. Until then I’m stuck with my cheesy 14”, under powered bandsaw with shop built table/fence with max re-saw capacity of 5”. It’s by far the most finicky tool in my shop. Seems like I always have to readjust everything to get decent resaw results. Realistically my best bet is just to use some kind of a “point” fence and manually steer the work piece on the layout line because my fence doesn’t work worth a darn.

After re sawing I joint edges for gluing up into a larger panel.

Reply With Quote

Reply With Quote