Somehow I can’t get the pictures to rotate into the correct orientation on Photobucket, but you’ll get the idea.

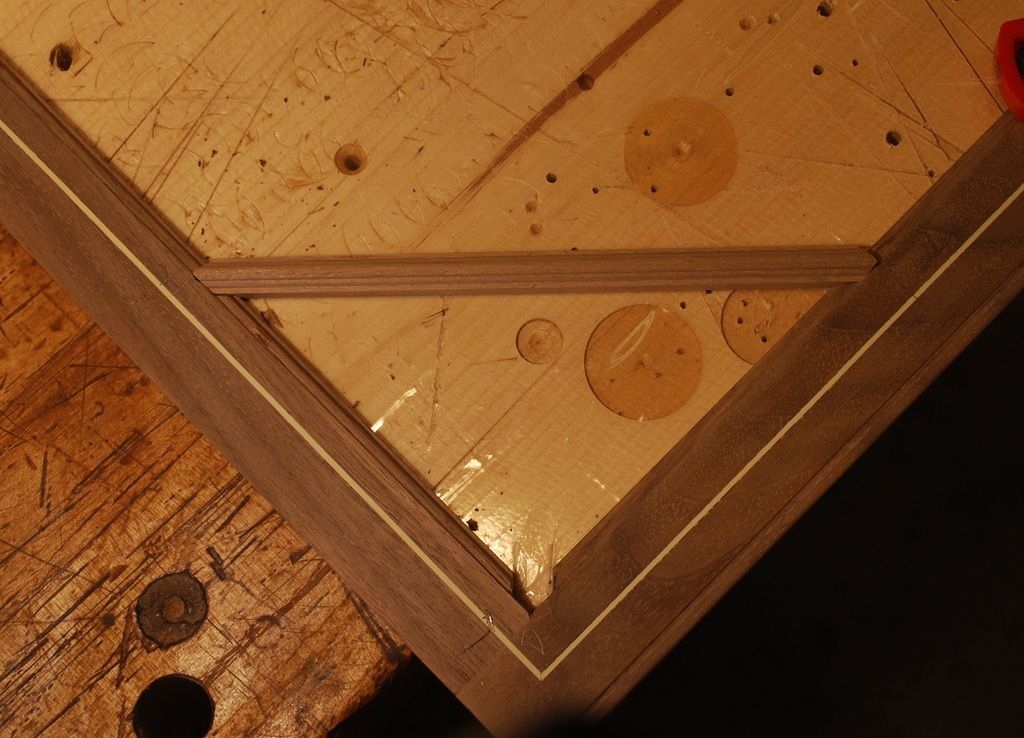

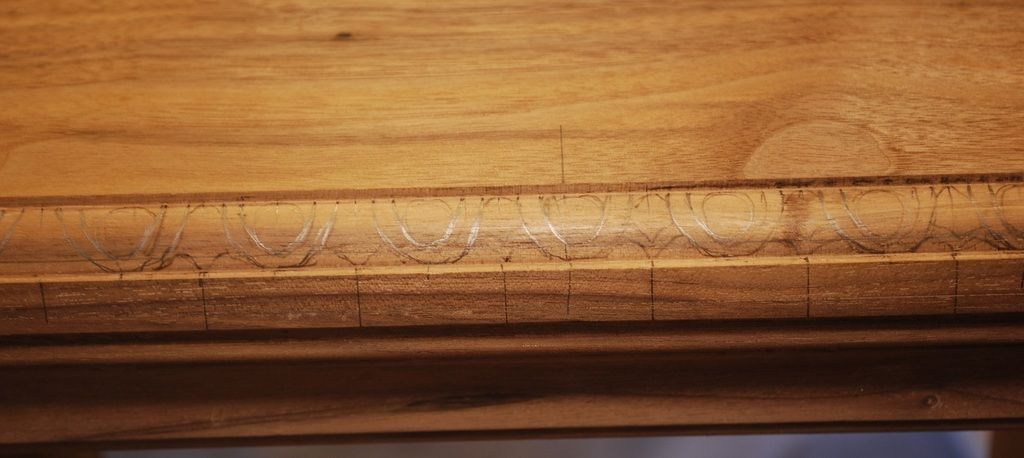

Here’s the profile of the cornice molding drawn on the end grain. I use a shop made rabbit plane to create the initial rabbit farthest from the reference edge.

N

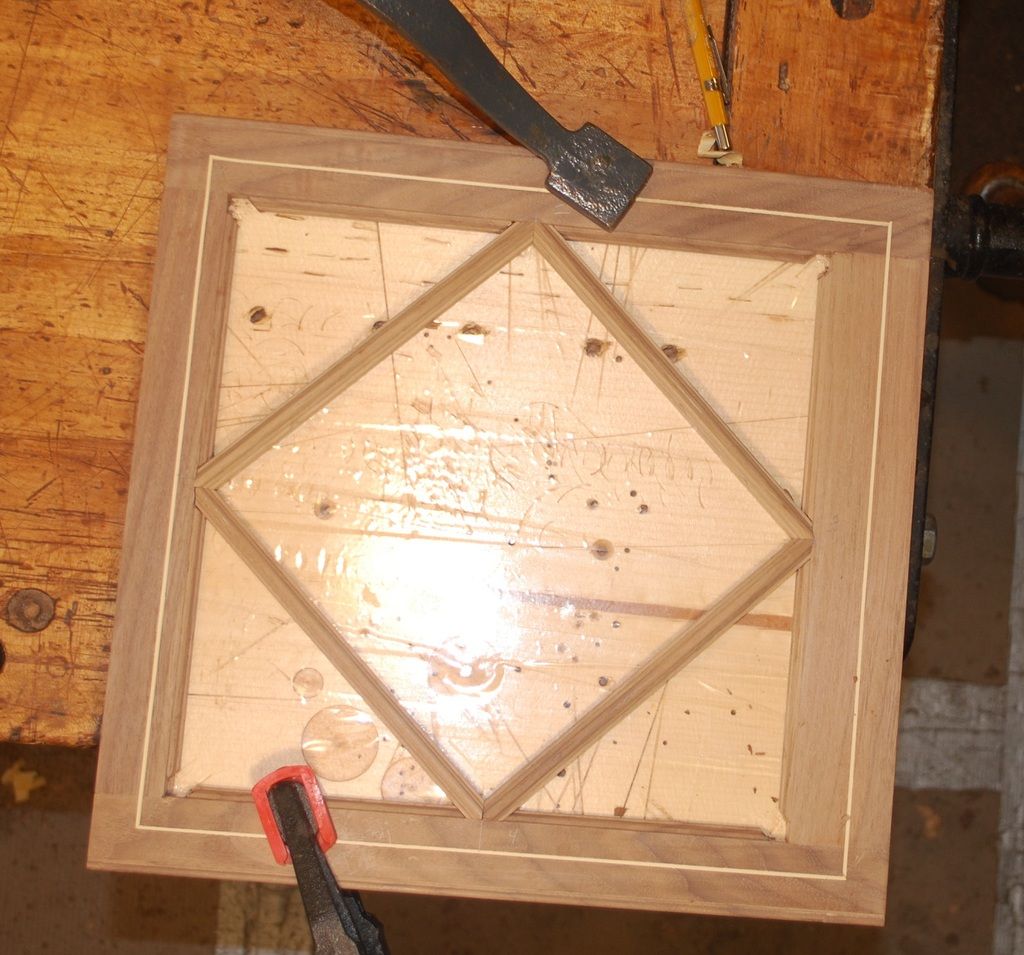

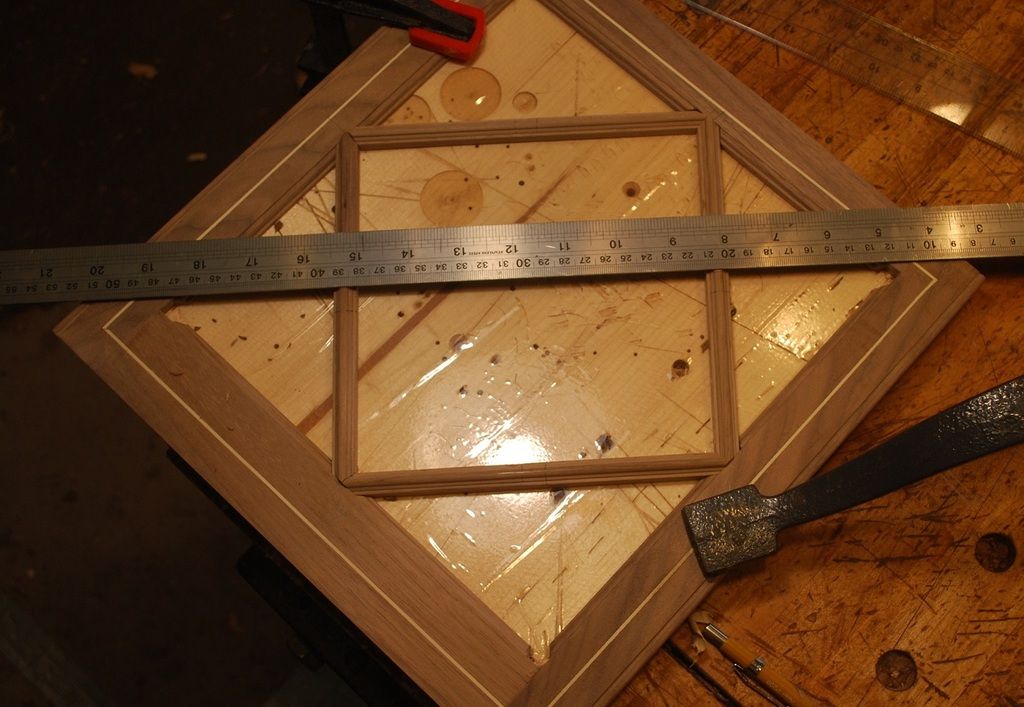

Next I use a plow plane to create the rabbit that defines the middle of the bottom concave curve.

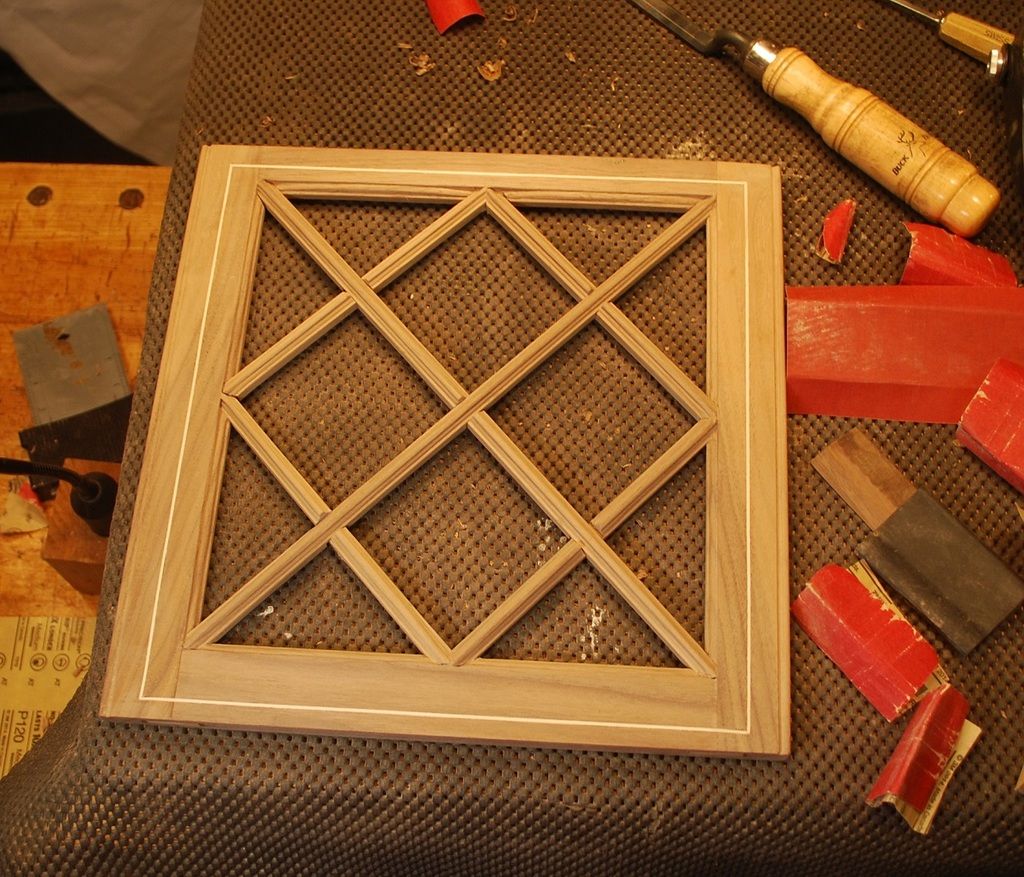

Using the # 6 and a # 12 hollow and round and the finished molding. Probably more time spent sharpening then planing.

Reply With Quote

Reply With Quote