I'd consider assembling the frames first, then running them through the table saw with a spline jig (assuming I understand desired result correctly). I've had success spreading wood glue on end grain with a couple of gaps and putting at least 2 drops of CA glue to hold them together instead of clamping. That should hold the frames together while cutting the slots for the splines on the table saw.

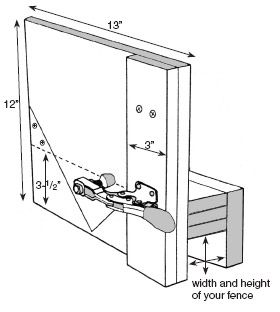

To clamp them this is a good option (or a similar brand as there are several out there) -

WoodRiver Self Squaring Frame Clamp . I have owned one of these since the 1970's when they were first available and they work great to clamp a picture frame square. If the capacity isn't large enough just buy a threaded rod with washers and wing nuts to the capacity you need. Then you can clamp much larger frames.

Also, as another said, if you either have or can borrow a Domino, that would be the most certain and strongest way to make these frames quickly.

Reply With Quote

Reply With Quote