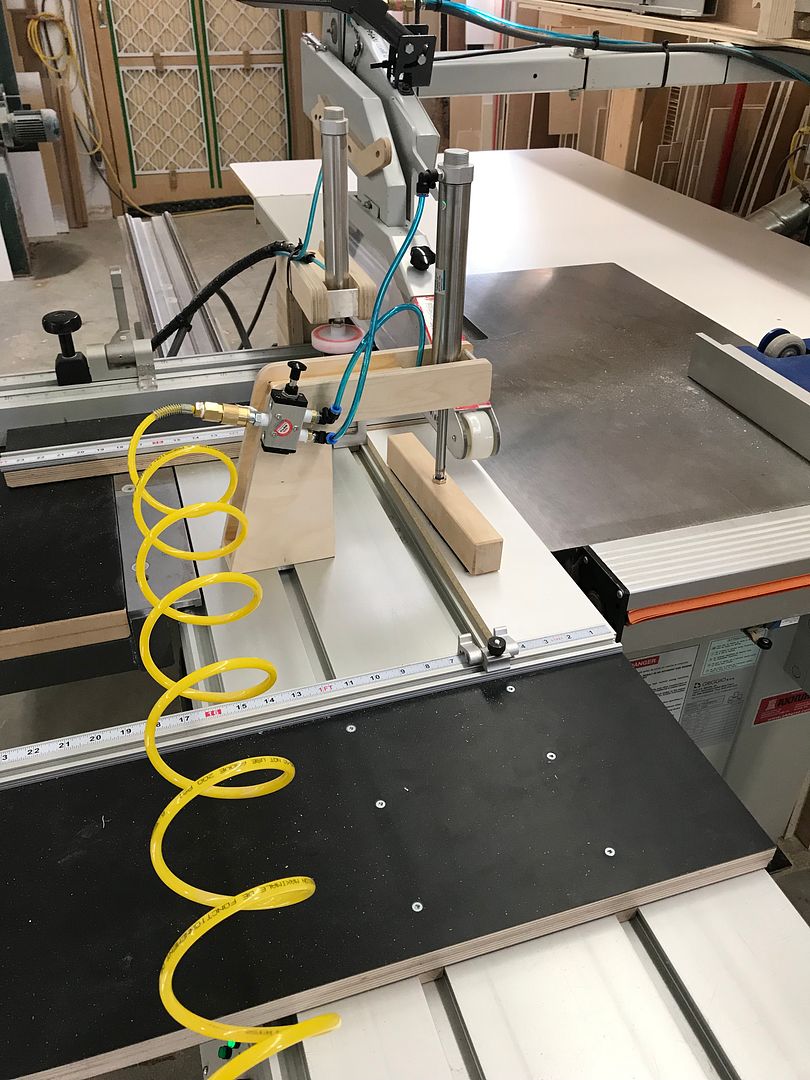

I was was cutting some parts today for melamine drawer boxes. Just thought I’d share how we dado the bottom groove. I reference all settings from the top edge, in this case the fritz/franz is used for placement while one of my shop made pneumatic clamps holds things firmly.

The dado also has a tendency to lift the material so this is far better than holding with hands never mind safer and less wear on the operator.

The clamp body is made from CNC’d Baltic birch, with integral aluminum pieces for strength all epoxied together. Cylinders and valves etc are all imports from Amazon. Work great and very reasonable cost.

Reply With Quote

Reply With Quote