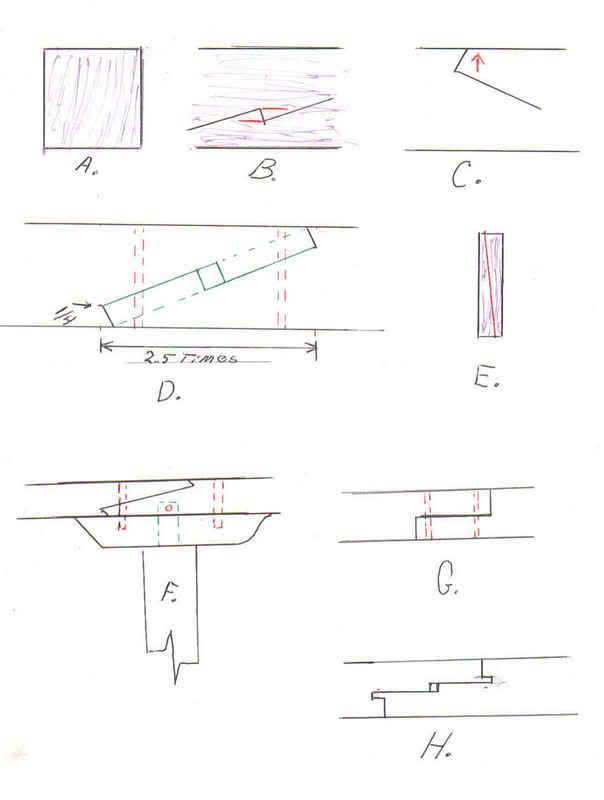

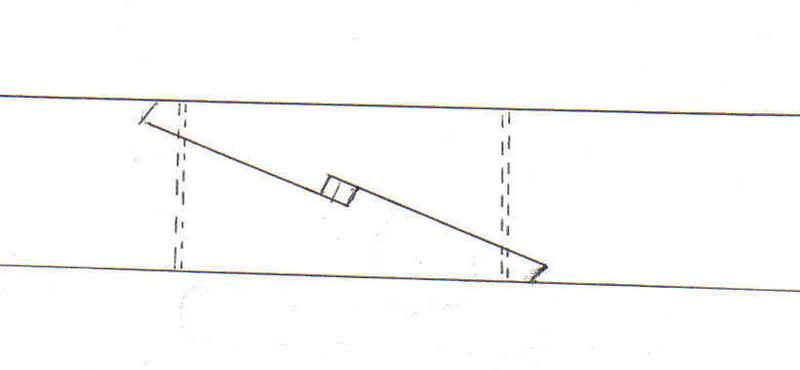

I am a little on the frugal side and sometimes use a Stopped, Splayed, Keyed, and Doweled Scarf Joint if I don't have a piece of 2 by 4 or such the right length. I realize its a timber framing joint and I like to make wood joints, besides to me it adds character to a piece and modern Woodworkers just look at the joints in wonder and scratch their heads.

Does anyone else do this?

Jr.

Jr.

Reply With Quote

Reply With Quote