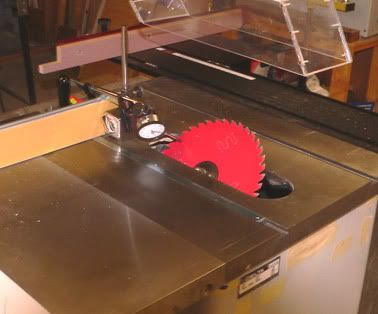

I'm having trouble cutting bevels on my table saw, with blade tilted to 45*, pushing 3/4" stock through with a Jess-Em slider. Saw is set up to tight tolerances, with no burning for any other cuts. I need to cut some 1 1/2 x 3/4" banding for my drill press table, thought this would be the best way to do it. All goes well until the piece gets about half way through the blade, then it burns the top 1/4" or so of the workpiece, not the off cut , only where the teeth stand proud of the blade. It is probably limited to the the top portion of the cut because the sliding table prevents the workpiece from going all the way through the blade. The slider is aligned to the blade so that a five cut check reveals only about .003 on the 5th cut.

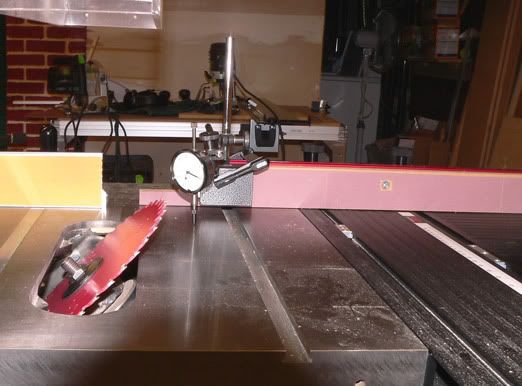

It's a fairly new Freud fusion blade, which performs very well on other cuts. I figure the blade must not be aligned to the table in the 45* position, (it's within about .001 or so when 90* to the table) but how does one go about adjusting that? I'll check it with my dial indicator tomorrow. I have a 2 year old left tilt Delta Unisaw. Thanks much.

Dan

Reply With Quote

Reply With Quote Life is a gift, not a guarantee.

Life is a gift, not a guarantee.