I've been using LV's trio of BU planes for a few weeks now and I have some comments on limitations of the BU design.

I prescribe to Chris Schwarz's recommendation of after using powered jointer and planer to mill lumber, use a jointer plane to flatten/remove machine marks followed by a smoother for final surface prep. He also recommends cambered irons for the jointer and smoother plane, with the jointer having more camber (and the ability to take a thicker shaving) and the smoother having less camber (and obviously a finer shaving). But the BU design has a significant limitation to cambering. It has to do with the bed angle.

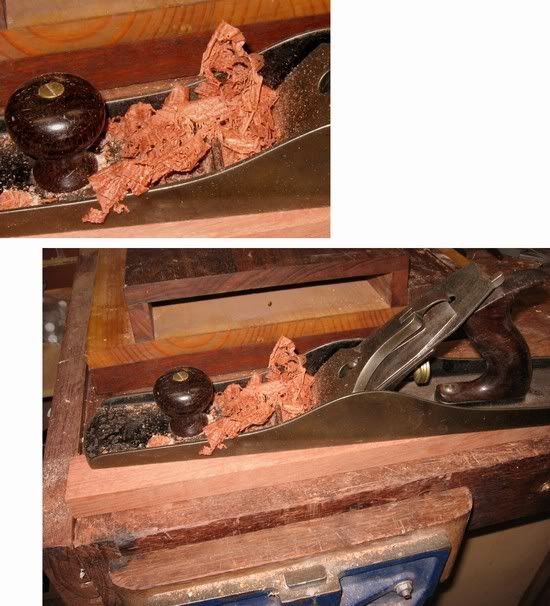

Using a cambered blade, you project the iron just far enough so the corners just disappear into the sole. This will eliminate planer tracks. So how far you can project your iron depends on the camber. And the projection determines the thickness of shaving.

So doing a little trig: On a standard angle plane with bed angle 45 degrees, if you want a 5-6 thou shaving (Chris' recommendation for a jointer plane), you need to have a camber of about 7-8.5 thou. This is coincidentally the amount Chris mentions on his video (that's a good sanity check on the math). However, on a BU plane, the bed angle is 12 degrees, which works out to be a 24-29 thou camber! That's huge.

It's not so bad on a smoother (max 1.5 thou shaving) though. The camber needed for a standard angle is just over 2 thou (again the same number Chris mentions). And for a BU, the camber is just over 7.

So what conclusions can I draw from this?

If you want to follow Chris's method and camber your jointer, a BD jointer would be better (my opinion) than BU.

The smoothers I'm undecided on. On one hand you have BU's ability to easily change angles with different blades (but of course you can use different blades with back bevels for the standard angle), you can close the mouth tighter since there's no chip breaker, and you can use a low angle iron for end grain work.

But how often do you use a smoother for end grain, especially if you have a block plane? And a sharp iron on a standard angle can easily handle end grain anyways.

Or if you like the BU design jointer, you can always not camber your iron and use your smoother to get rid of the plane tracks.

Final thoughts: In the BU vs BD debate, it always comes down to the universal answer: "It depends".

Reply With Quote

Reply With Quote

but it's probably just the server at work...

but it's probably just the server at work...