Hello,

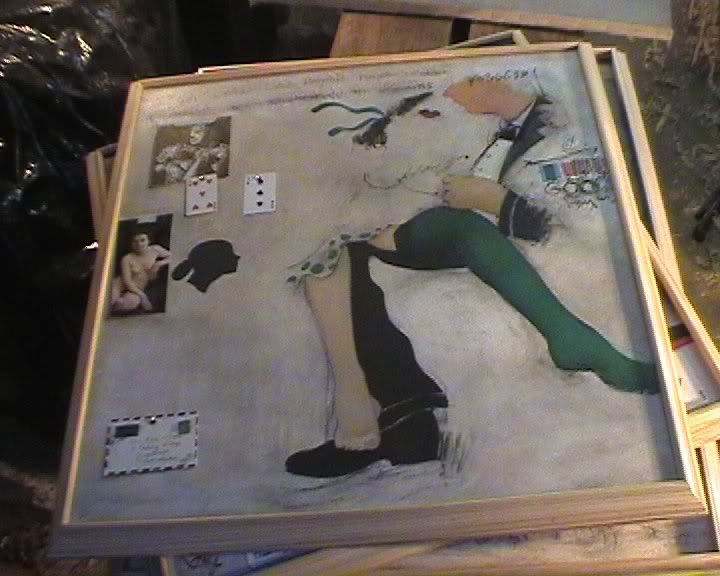

Here's some photos of how I made up some picture frames for my father in law. He stretches his own canvas and asks me to frame them on occation.

I've just made these out of pine. I went for the cheapest planeable pine I could find to keep the cost down. Normally I buy that M12 stuff. Just regular construction grade stuff. $3/m at bunnings. Full of knots though. So you have to be pretty selective. Cut it out between the knots.

See, my father in law likes to paint his frames to ensure the colours work well with the painting etc. Subtle arty stuff I don't really understand very well. But, it means that it doesn't really matter what wood I use since it will be painted.

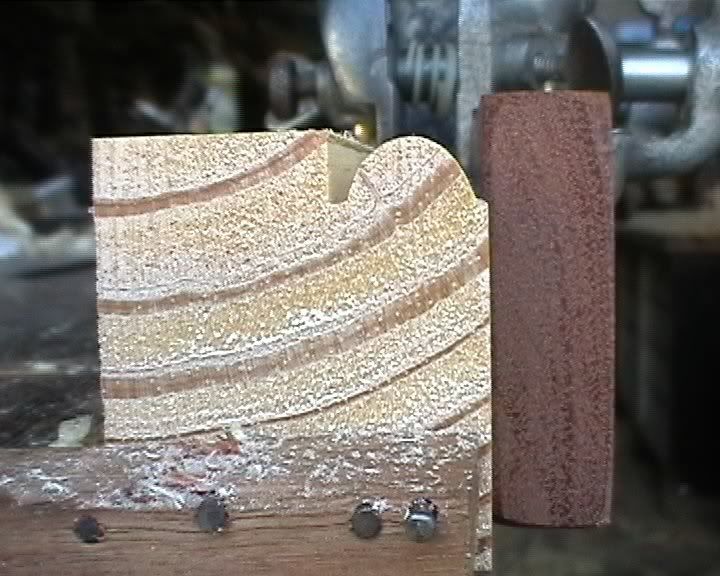

This ones been cut from thicknessed stock about 52x40.

Fillet at the top. Then a couple of ogees seperated by another fillet. Don't ask me whats its proper name would be.

I'm not overly keen on it myself, but my FIL thinks it suits his painting. So alls well. He'd know.

This profile was made with a couple of blades in a stanley 55.

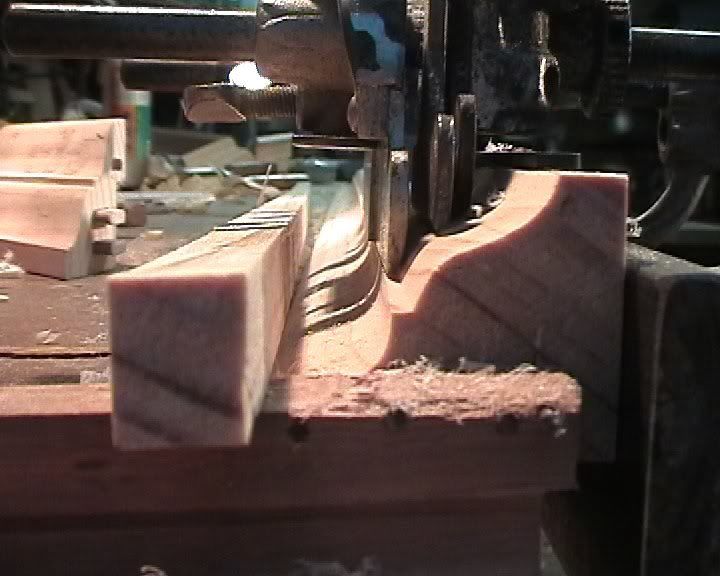

The first blade drops down like this.

Lot of stock to remove as you can see. Cut needs to drop something like 25mm. So coarse shavings a must, or else it'll take too long. Left hand depth stops and reverse profiles allow that. As coarse a shaving as you can go whilst maintaining control and finish. For those who like to measure shaving thicknesses with calipers, for this frame I had the blade set to take 0.4mm shavings. Any more and she got too hard to push.

You can try and speed up the process with plough cuts first to take out most of it. Ripping through on the table saw quickist I've found. But, I've found its actually quicker avoiding all that and just drop the cut with the blade set for a coarse shaving. Less stuffing about.

Since I have to change the blade latter, I put this cut into all the pieces now.

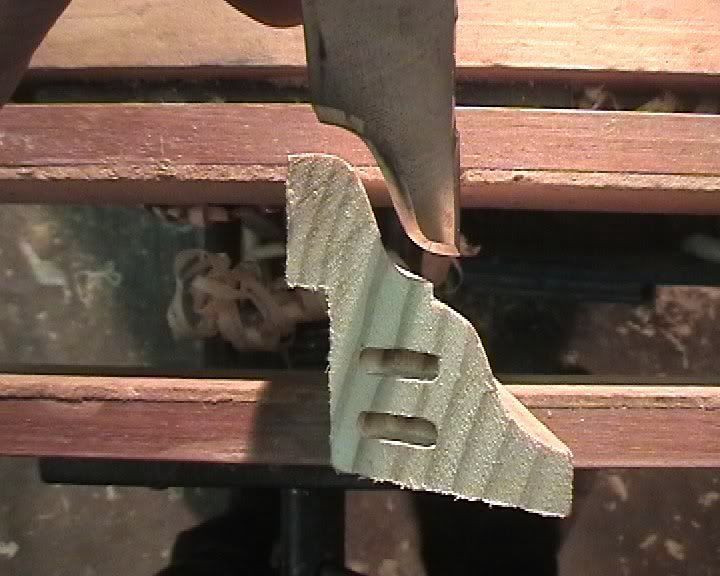

I now cut the rebates for the canvas to sit in.

With that done, I switch to another blade that intercepts the other cut. Comes down like this sort of thing.

Leaving an offcut, which will probably end up being used for stirring paint.

Reply With Quote

Reply With Quote