I don't normally make tool gloat postings, but I am kind of psyched about trying this sander out, and I've never used anything like this before.

So has anyone used one of these mini detail belt sanders for woodworking? I know they are normally used in metal fabrication because the first time I ever saw one was on one of those car or motorcycle building TV shows. When I first saw the sander I thought it was kind of cool, but didnít know where I could find one. It wasnít until just a few weeks ago that I discovered it was a Dynabrade sander. Heck, Iíve got 3 Dynabrade ROS sanders, but I never knew they made these sanders too.

Well, 2 days ago Philly Tools gave me one of these Dynabrade Mini DynaFile II Kits in exchange for some stuff I am doing for them (ya, it sucks to be me).

I havenít had the chance to play with it yet, but the reason I asked them to send me one was so I could try it out on an old hollow spiral turning project that has been sitting in the corner of the workshop for close to 5 years now. I started these hollow spiral turned columns for my fireplace surround, but I never finished them because the sanding was killing me. I am hoping that the mini belt sander is going to work a lot better than the little drum sanders I was originally using (and eventually gave up on).

Iím thinking the belt sander is going to fly through this project, but if nothing else, it should give me a heck of a lot more control over where I sand compared to the round drums. The kit came with the standard 1/2" x 3/4" platen, but also includes the 1/2" x 1/4" platen, plus the curved wheel-thingy for doing inside corners. Oh, that little black thing in the corner is a 1/4" collet so I can also use this as a right-angle die grinder.

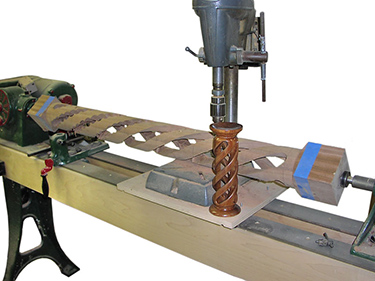

(This is an old picture of the spiral turning, but is the only one I have at the moment. That's an old drillpress I mounted to a rolling carriage on the lathe, and I used it to drive the forstner bits and sanding drums down the center of the spiral to shape it.)

Reply With Quote

Reply With Quote

Please help support the Creek.

Please help support the Creek.