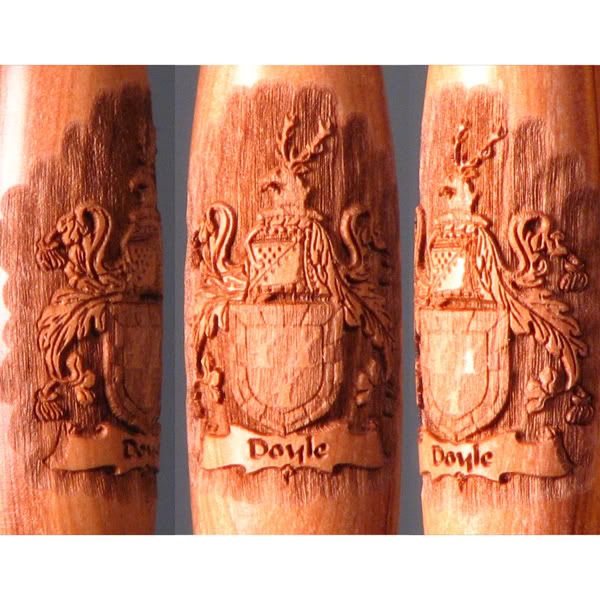

Here is another one of my engraved pens. I modified the coat of arms to get a nice carved affect. There is a lot more detail in this design than on my earlier post of the Claddagh pen, so it is tough to go as deep. I think I have most of the bugs worked out.

Reply With Quote

Reply With Quote