There have been a lot of discussions here about whether a table saw should be left tilt or right tilt. I am the first to admit I am a right tilt guy, and have a right tilt Unisaw. There are some good arguments for both.

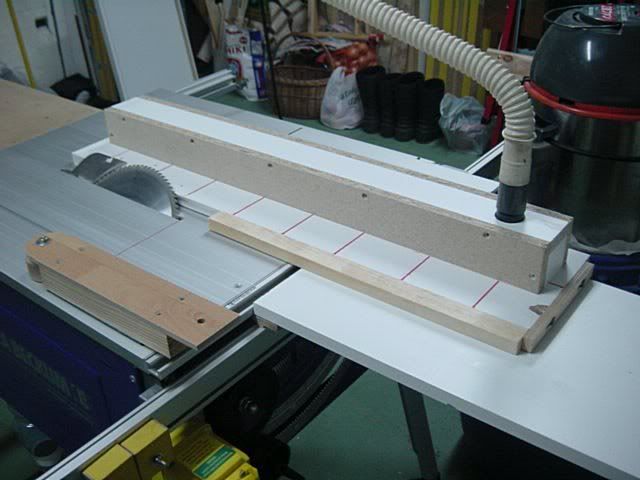

BUT....one reallllly good reason for buying a left tilt saw is if you may upgrade to a sliding table. When you install the table the best way is to remove the left wing, and shorten the fence rail on that side. This makes it almost impossible to use the fence to the left of the blade, meaning you cannot bevel safely anymore. Don't ask how I know this.

So.....with head hanging, I must admit that if I were buying a new saw, it would be left tilt.

Rick Potter

Reply With Quote

Reply With Quote