Gregg,

The handle is a 13/16 opening, and you can put all sorts of 3/4 inch and smaller cutting accessories in it if you have the adapters.

Curtis,

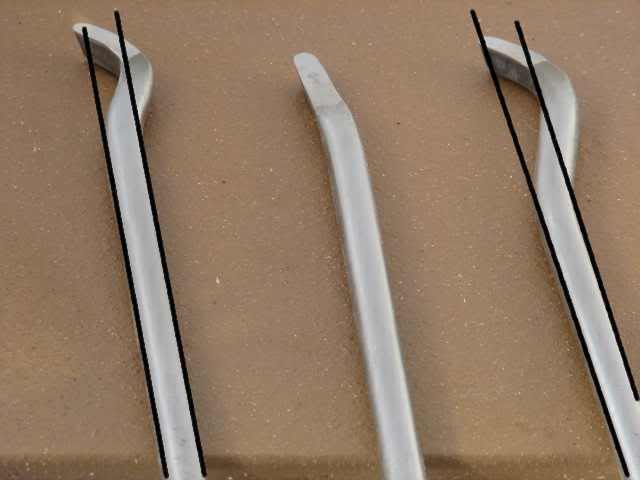

Actually, that isn't safe. If you have hollowed with one of the goose neck tools, you have to have the curve off the tool rest, otherwise the tool will twist out of your hand. The McNaughton has vertical support fingers for the blades to go into to keep this twisting from happening.

Rasmus, I will sent you a PM

robo hippy

Reply With Quote

Reply With Quote

. Beat me up pretty bad and I stopped.

. Beat me up pretty bad and I stopped.