I agree with others that a tailstock is important. Also someone else mentioned ebay. I looked and there are quite a few headstocks and tailstocks for sale.

The heaviest looking one to me was from a SENECA FALLS LATHE. It would have to be converted from gear to pulley but they state the headstock is about 100 pounds (currently $25 and no bids).

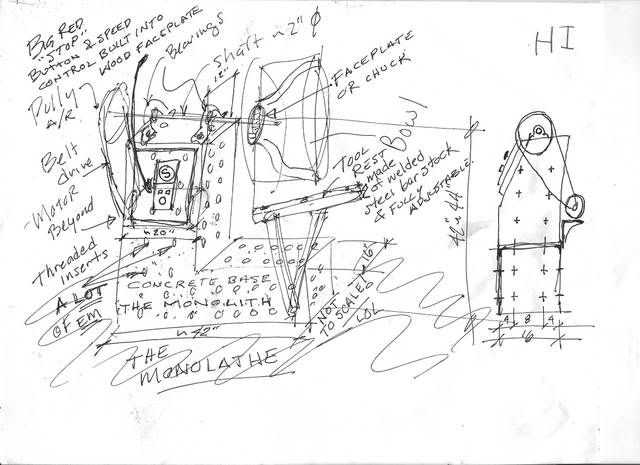

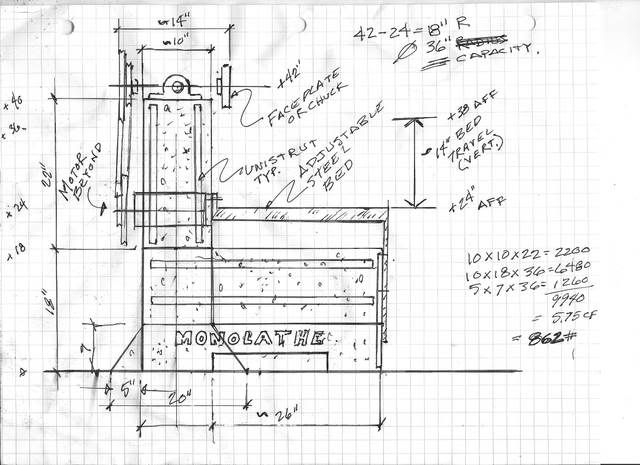

If you have the place to put it, I like the idea of concrete base also.

Look forward to seeing pics as it comes along.

Mike

"I became insane, with long intervals of horrible sanity." - Edgar Allan Poe

Reply With Quote

Reply With Quote