Man, I spend a lot of time taking it all apart just to put it back together

The box that will house the big red "STOP" button

Getting ready to invert it for the casting..

(I will take the pulley off the spindle) the spindle needs to be in place when casting the concrete to keep the pillow block bearings aligned.

The front...

and the back.

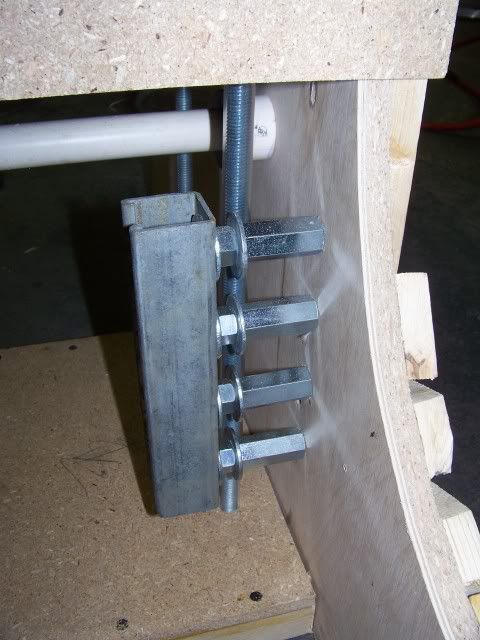

This will be the adjustable mounting for the motor tensioner:

Reply With Quote

Reply With Quote

Is it Friday yet? I just don't have the energy to do it on a weeknight after a long day at work. Mixing eight or ten bags of concrete is do-able if I was doing fence posts but placing it in the form and making sure all is right needs me to be at my best. I only have one shot at it really and I want to be proud of it. My flagship so to say..

Is it Friday yet? I just don't have the energy to do it on a weeknight after a long day at work. Mixing eight or ten bags of concrete is do-able if I was doing fence posts but placing it in the form and making sure all is right needs me to be at my best. I only have one shot at it really and I want to be proud of it. My flagship so to say..