Apologies in advance for the long post.

I've recently gotten the woodworking bug and ever since, I've been devouring information from forums like these. But I'd like to ask for some recommendations specific to my situation if I could...

I've budgeted $800-1000 for purchasing a new tool or tools in the next couple of weeks and I'm trying to figure out which path to follow.

Some details - I'm interested in building solid-body electric guitars, some small home furniture projects (bookshelves, etc.), some modest home improvement/repair, trim work, etc.

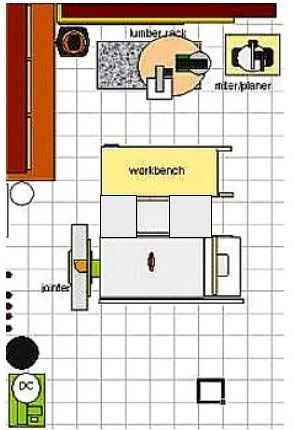

My shop is actually an old springhouse. Roughly 16x19. One 40" entry door with a few steps leading up to it. It has it's own sub-panel piggy-backed off the house panel. No 220, but 6 or 8 individual 120 circuits, some 15A and some 20A.

My tool arsenal so far consists of....

10" Delta power miter saw (not great, but decent)

PC 690 Router in a Bosch router table with a small assortment of decent bits.

Ryobi 12" drill press

Ryobi 9" bandsaw (the only purchase so far that I regret)

Skilsaw circular saw (old and not great)

Delta 1HP DC and DIY air filter (window fan/furnace filter setup)

big ShopVac

a good makita cordless drill/driver, a couple palm sanders, a couple jig saws, hand saws, a kreg screw jig, not enough clamps, a dovetail jig, and other assorted stuff

The obvious first choice was a table saw. But I'm hurting for space here, and safety is a concern due to my inexperience. And again, no 220.

Tied for first is a real workbench.

So I've been thinking of maybe an EZ saw track setup and new circular saw to supplant the table saw for breaking down sheet goods for the bookshelves and things. And maybe it could be incorporated into a bench that would serve regular bench duty when I'm not using the EZ?

Other ideas....a second and maybe third 690 to keep for non-table use? (Lots of routing involved in the guitar building!)

Maybe a small compressor for finish nailing and general shop/house use?

More and better clamps, bits, rules, etc. are a given and will be part of the plan as are the consumables - lumber, fasteners, sandpaper, etc.

I'd love to hear other ideas...maybe hopefully things I haven't even considered yet. Keep in mind I'm stuck with buying new most of the time - not a lot of craigslist activity in my neck of the woods, for example.

Reply With Quote

Reply With Quote

!

!

) That'll open up more options for you.

) That'll open up more options for you.