Hey, all, I did a search but didn't come up with a lot that addressed my questions.

I'm slowly getting into more hand tool woodworking (using hand planes for scarfing plywood; messing with drawknives and spokeshaves, also some woodcarving) and have an increasing need to sharpen fairly frequently, and often remove nicks in edges or flatten stuff ... but I can't wrap my Neander head around spending the $$$$ for a Tormek and all the jig$$$ you need to use it, so I was considering getting a decent belt/disk sander like the Jet JSG-960S.

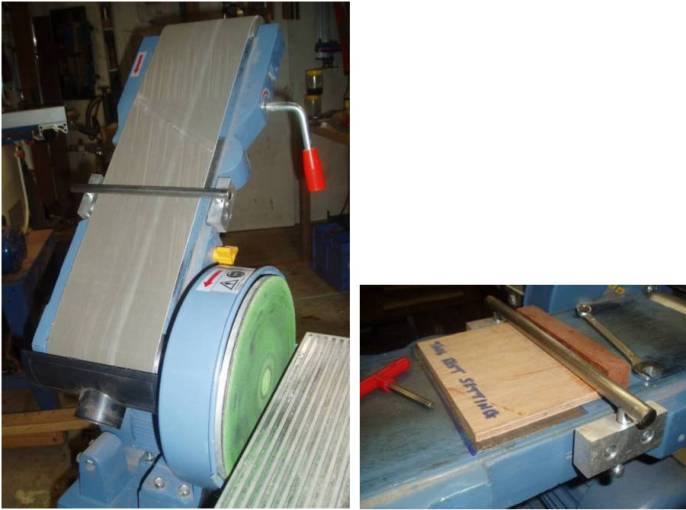

That way, I figure the machine could be used for woodworking, and if I weld up a few jigs, I could also use it for sharpening ... and it would also be useful for metalworking.

Do many of you use stationary belt sanders in this way, and what are the pros and cons in your experience?

Thanks in advance for any insights.

Reply With Quote

Reply With Quote