Before getting my 1984 Powermatic 1150 into usable shape I needed a larger table. I have done a lot of research and settled on a Mr. Sawdust-ish table with steel reinforcement to insure that the two layers of MDF won't sag. I started off with a trip to Woodcraft which led me to purchase many pieces made by Incra including T-Track, stops and clamps.

The table itself is 18"x28" and is two layer of sandwiched MDF, the steel re-inforcement strips are 1/8"x1/2".

I finally got to put my 1940's Unisaw to good use by using the table as cauls, restoration to follow. The steel strips were two-part epoxied into place and then the MDF was glued together with regular wood glue. Also, you can see the shop supervisors in this picture!

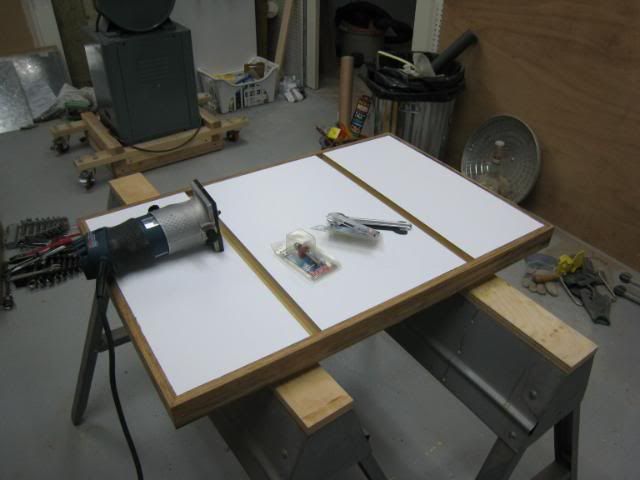

Next up was covering the top and bottom of the table in formica. The dowel rods are used to locate the formica without it touching the MDF, once they touch there is no getting them apart.

I then cut dadoes to receive T-Track and trimmed the outside with bamboo left over from the pallet that my homes flooring came in, I rounded the corners to remove all sharp edges.

The final step was getting it installed on my drill press. I still have to use a forstner bit to drill a hole in the table for replaceable ZCI, but I need to go to Woodcraft to buy a circle cutter. Also, you can see what a quick brainstorming session came up with for a turret handle for the drill press, FORE!

Any comments welcome and thanks for looking!

Reply With Quote

Reply With Quote