Hello Scott,

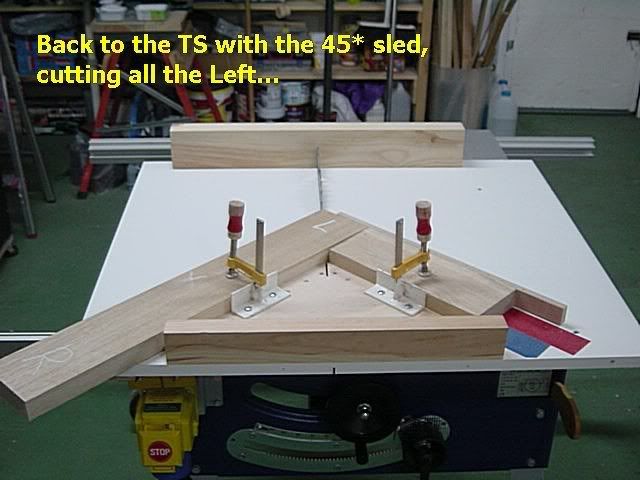

Having a good known true platform - the large sled - makes cutting and fitting a smaller sled a breeze.

Also, using the large sled as a known good reference, I can set the fence true instantly & w/out having to make a lot of adjustments & adjustment cuts.

Reply With Quote

Reply With Quote ). But after using the heck out of it, my plans for the next sled call for much larger. Right now I'm thinking at least as wide as the saw top and as much front to back size as I can lift without killing myself.

). But after using the heck out of it, my plans for the next sled call for much larger. Right now I'm thinking at least as wide as the saw top and as much front to back size as I can lift without killing myself.