I need some "where do I go from here" advice. I am setting up my Grizzly G0661 table saw. I am using my 12" Starrett combo square to check everything. The blade, an Infinity Super General, is 90 degrees to the table and shows almost no run out using a dial indicator. I checked the miter slot to blade parallel using a block of wood clamped to my miter gauge with a screw in the end of it (saw that tip on here). The head of the screw just touches the same tooth at the front and back locations. My miter gauge, Osborne EB-3, was checked and set to 90 degrees. So, I'm going to say that my miter slot is parallel to my blade and my miter gauge is 90 degrees to my blade. And yet, I cannot make a 90 degree cut when checked with the combo square. So I did a little test. I kept adjusting my miter gauge until the cut came off a perfect 90 degrees. I then checked the angle from the blade to the miter gauge and it is between 91 and 92 degrees. This makes me think my miter slot is not parallel to my blade, but everything above says otherwise. Could the Starrett combo square be that off? I finally had to put everything away last night since I was so frustrated. Frustration + table saw = bad idea! Any suggestions? Anyone in Chicago want to trade some "set up knowledge" for a big helping of smoked carnitas?

Reply With Quote

Reply With Quote

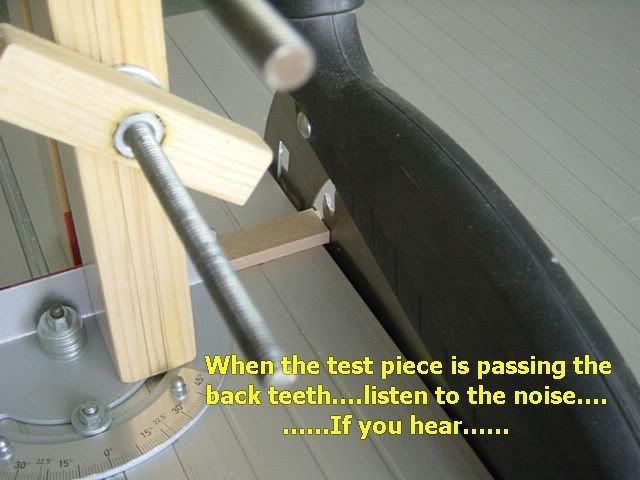

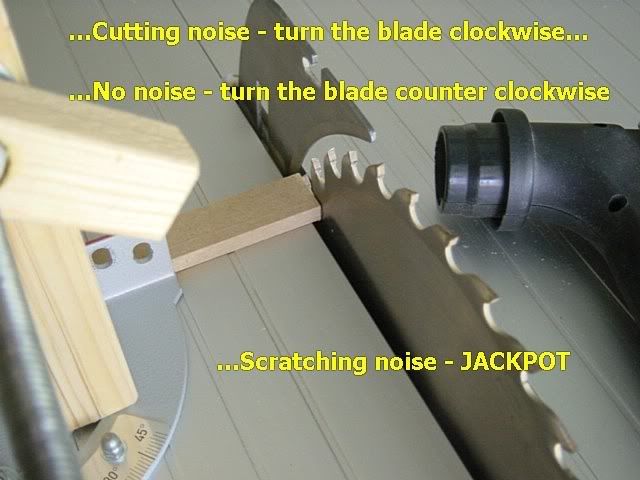

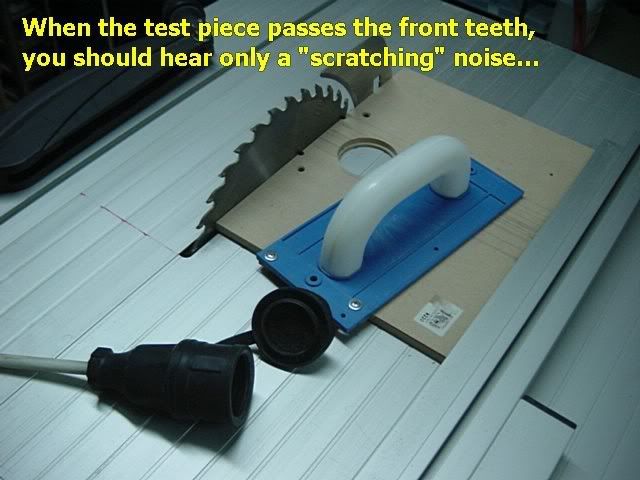

I clamped the wood to the miter gauge each time and noticed something. I pushed the wood all the way thru the blade and after cutting with the front teeth, the back teeth also made a small cut. I'm going to say that this means the blade is not parallel to the miter slot. Before cutting anything I used my dial indicator, as stated above, and the difference from front to back was .003. Would that really make that much of a difference? I was really hoping that wasn't the problem since it looks like a pain to loosen six bolts under the table top. How do you get small, accurate adjustments?

I clamped the wood to the miter gauge each time and noticed something. I pushed the wood all the way thru the blade and after cutting with the front teeth, the back teeth also made a small cut. I'm going to say that this means the blade is not parallel to the miter slot. Before cutting anything I used my dial indicator, as stated above, and the difference from front to back was .003. Would that really make that much of a difference? I was really hoping that wasn't the problem since it looks like a pain to loosen six bolts under the table top. How do you get small, accurate adjustments?