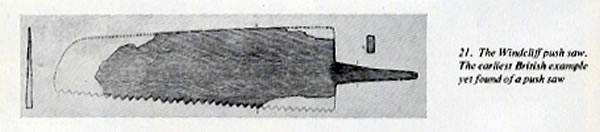

Mike and all: It was never my job to research the tools we made. We were supplied with old tools or drawings to work from. Research was done by the curator. The curator of tools,Jay Gaynor, gave me the specifications to work to on the saws,with drawings of the handles. I went by what he told me at the time,and was highly relieved that I did not have to build a machine to taper grind the saws.

So,you are saying the half rip had a variance of .004" max taper,only at the tip end of the saw? Then only the other saw had a real taper? The fact that the toothed edge varies so much (.006") in itself makes me wonder if Jay just considered those rather random thicknesses as inaccuracies in the 18th.C. rolling mill. Maybe that's where he was coming from?

I happened to be down to Williamsburg today(The first time in months.The employee sale was on),and saw Jay. He said he hadn't seen the pictures yet,as he had been in a meeting. He did repeat that he did not think there was enough of a taper to confirm that it really was one. And,apparently only the "pannel" saw actually has much taper to it. I am not sure what that means since the cutting edge itself is so tapered.

This is not a pi$$ing contest. It is a discussion. Jay just said that we had months to examine the Seaton chest,and TTHS only had a day. He trusts his findings,but will review his figures and get back to me. I did look at the Seaton saws,and put a dial caliper on them here and there,but ultimately the decisions were his as curator. Of course,I was interested in all the tools in the chest,not just the saws. There were saw files still wrapped in their original paper.Chisels too. I was intrigued by the carpenter's pencil,unused,that looked like a modern one,except the graphite did not go clear through like modern ones.

Reply With Quote

Reply With Quote