I've searched quite a bit on this and can't find the answer, so I apologize if this has been covered before.

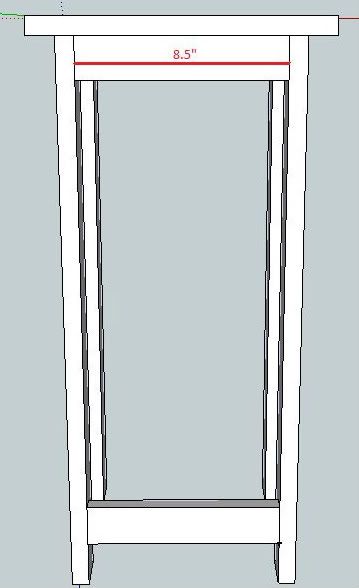

The following is a very crude squetchup of a plant stand I'm doing. In the space that has 8 1/2" across, I want 5 spindles 3/4" wide. How do I come up with the right spacing? I know there is an easy way to do this but I can't quite get it figured out.

Thanks in advance!

Jeff King

Reply With Quote

Reply With Quote