Probably not, actually. I think you'll find the SMC fora to be of a different caliber than the typical online forum. We tend to police ourselves, mostly, with the administrators to do the actual dirty work. The admins also do not take a hands-off approach as you'll find in many online forums, where action happens weeks or months after a transgression occurs, as the owner of the board is a very active member. You'll get a fair warning once, maybe twice, but continue to break the rules and you'll find yourself banned in very short order. On other forums there are usually plenty of members who back up posting shenanigans... you won't find such people here. We love the community created here, and none of us will stand idly by while someone, new or old, trashes it.

Hi-Tec Designs, LLC -- Owner (and self-proclaimed LED guru)

Trotec 80W Speedy 300 laser w/everything

CAMaster Stinger CNC (25" x 36" x 5")

USCutter 24" LaserPoint Vinyl Cutter

Jet JWBS-18QT-3 18", 3HP bandsaw

Robust Beauty 25"x52" wood lathe w/everything

Jet BD-920W 9"x20" metal lathe

Delta 18-900L 18" drill press

Flame Polisher (ooooh, FIRE!)

Freeware: InkScape, Paint.NET, DoubleCAD XT

Paidware: Wacom Intuos4 (Large), CorelDRAW X5

Dan, I think he meant someone will try the dry wall mix now

Lasers : Trotec Speedy 300 75W, Trotec Speedy 300 80W, Galvo Fiber Laser 20W

Printers : Mimaki UJF-6042 UV Flatbed Printer , HP Designjet L26500 61" Wide Format Latex Printer, Summa S140-T 48" Vinyl Plotter

Router : ShopBot 48" x 96" CNC Router Rotary Engravers : (2) Xenetech XOT 16 x 25 Rotary Engravers

Real name Steve but that name was taken on the forum. Used Middle name. Call me Steve or Scott, doesn't matter.

Yoga class makes me feel like a total stud, mostly because I'm about as flexible as a 2x4.

"Design"? Possibly. "Intelligent"? Sure doesn't look like it from this angle.

We used to be hunter gatherers. Now we're shopper borrowers.

The three most important words in the English language: "Front Towards Enemy".

The world makes a lot more sense when you remember that Butthead was the smart one.

You can never be too rich, too thin, or have too much ammo.

Sorry, I still had the quote from the last post (Lee's) from the prior page. Ignore my comment...

Hi-Tec Designs, LLC -- Owner (and self-proclaimed LED guru)

Trotec 80W Speedy 300 laser w/everything

CAMaster Stinger CNC (25" x 36" x 5")

USCutter 24" LaserPoint Vinyl Cutter

Jet JWBS-18QT-3 18", 3HP bandsaw

Robust Beauty 25"x52" wood lathe w/everything

Jet BD-920W 9"x20" metal lathe

Delta 18-900L 18" drill press

Flame Polisher (ooooh, FIRE!)

Freeware: InkScape, Paint.NET, DoubleCAD XT

Paidware: Wacom Intuos4 (Large), CorelDRAW X5

Sergio, are you actually getting colors by changing power? I haven't seen that change, but it could have to do with application. Bonding seems better than cermark on the aluminum pieces I've tested so far, inferior on nickel plating. Really an interesting experimentIs the color chart raster or vector engraving? The power is substantially greater in vector at the same speeds, I'm trying to get a handle on that color thing.

Epilog Mini 24 45W/various other dangerous implements the wife has ok'd over the years

Last edited by Sergio Arze; 12-06-2009 at 9:14 PM.

Machinaria M350 laser engraver

CorelDRAW X3

CorelDRAW 12

PhotoGrav3

Before I forget!!, you can also use the mix to cut on aluminum foil, if you are reducing with alcohol make sure to let your formula dry completely before vector cutting. I recommend 100%power and for speed use something equivalent to you laser power in mm/s

for example a 35watt machine 35mm/s.

Machinaria M350 laser engraver

CorelDRAW X3

CorelDRAW 12

PhotoGrav3

I tried that using cermark once, no luck. This stuff seems to have a real affinity for aluminum, thanks for the latest hot tip

Epilog Mini 24 45W/various other dangerous implements the wife has ok'd over the years

Epilog 24TT(somewhere between 35-45 watts), CorelX4, Photograv(the old one, it works!), HotStamping, Pantograph, Vulcanizer, PolymerPlatemaker, Sandblasting Cabinet, and a 30 year collection of Assorted 'Junque'

Every time you make a typo, the errorists win

I Have to think outside the box.. I don't fit in it anymore

Experience is a wonderful thing.

It enables you to recognize a mistake when you make it again.

Every silver lining has a cloud around it

Machinaria M350 laser engraver

CorelDRAW X3

CorelDRAW 12

PhotoGrav3

If anyone does try the drywall compound thing, there is a finer mix or premix that is used for the finishing coat. This finer grained compound might produce better results.

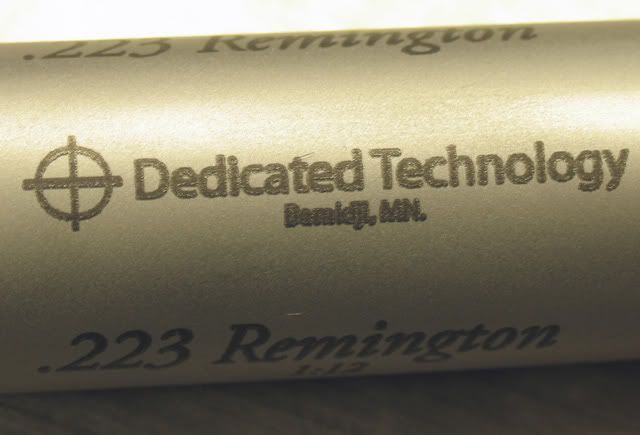

I have been following this thread with great interest. I am a custom gun builder, and have been looking, for YEARS for a good way to mark on stainless barrels. I have purchased special stamp-sets, and many other methods, but have yet to come up with a method that was good enough to show.

I just picked up my laser engraver. It's a 100 Watt ULS. I have very little time with it, but this morning I decided to get the recommended materials from Sergio's shopping-list.

I mixed the Mothers chrome polish 1:1 by weight with the plaster of Paris. At that ratio, it made a "catsup" like consistency. I took a cut-off chunk of barrel material (416 ss) and rubbed the paste on with my finger. I smoothed it out as best I could, and let it dry.

I Started at 70% power and 6% speed, and worked up and down with power and speed, documenting the settings. The result, regardless of the settings, were quite similar. I tried steel-wool on the printing, then sand-paper, and it held up well. It looks to be VERY durable.

After several different tries, the paste started to dry. I added a little rubbing alcohol, stirred it up, and it worked great!

Here are a couple of photos of the results.

what I really like about the formula is not that it just marks the steel but it actually engraves into it. I'm glad that this works for you

I'm currently working on a formula that will allow people to do the same dark engraving on aluminum, but it may take a few extra ingredients.

Machinaria M350 laser engraver

CorelDRAW X3

CorelDRAW 12

PhotoGrav3