A case of - "it ain't big 'nuf, but it ain't small 'nuf either!"

For my second bowl attempt I wanted to try a more rounded shape (to see if I could undercut a bit without blowing it up), and do then do a lid (curly maple) with a finial (ebonized walnut.)

So, I did the bowl, and didn't destroy it (it was iffy a couple of times!) -

1.jpg3.jpg

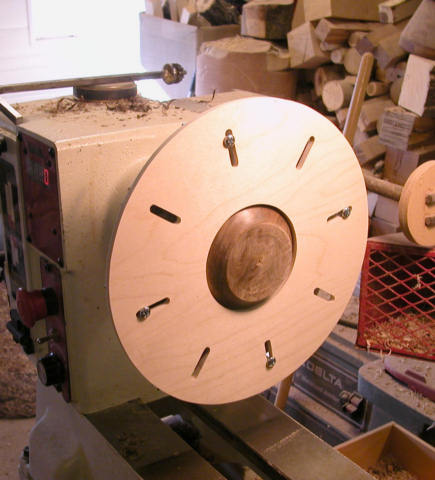

Then, I removed it and put my Cole jaws on the chuck, and did a quick measurement to set the bumpers - UH OH!!! The jaws won't go that small in expansion mode, and I can't grip this thing in contraction mode because of the shape!!

2.jpg

Well, I will just expand the 50mm jaws with some padding - NOPE!! Won't go that big!!

Right about here is where I realize that experience means everything!!One of you seasoned turners would have made this thing to fit your chuck rather than trying to make the chuck fit the piece.

Well, Sean Hughto, thanks for the recent pics!! I guess this bowl won't get finished until after Christmas, but at least I will own a donut chuck a little earlier than planned!

Reply With Quote

Reply With Quote