Well, there may be a couple of you who remember when I cut the plywood panels out of this project.

Cherry wood, 3 coats of amber shellac. Not my design, but I did make some very minor tweaks to the original.

Here it is finished and in use. I finished it up this past weekend.

New solid cherry side panels replaced the plywood. (Plywood was replaced because color match was not to my liking.)

Here is a view from the side.

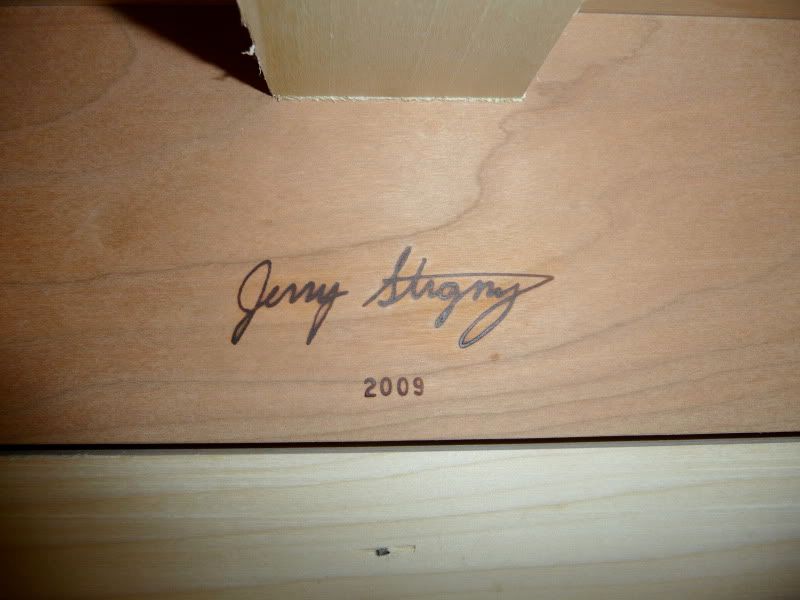

And lastly, I felt this project was worthy of my signature. So I pulled out my branding iron. (The majority of the project was done it 2009, so that is what I used for the date.)

Comments welcome. I'll start. I think the glued up panels could have better grain matching. My only issue is that the supplier I go to does not have a large section of cherry 4/4 select. I spent at least 2 hours to find what you see there. (That 2 hours is just for the panels...at least another hour for the rest of the wood.) And so sorry for the crappy pictures. I need to take a class or at least learn how to take the best with what you have.

Thanks for the community. I feel like I'm never that far away from some good advice.

Jerry

Reply With Quote

Reply With Quote