Hello everyone,

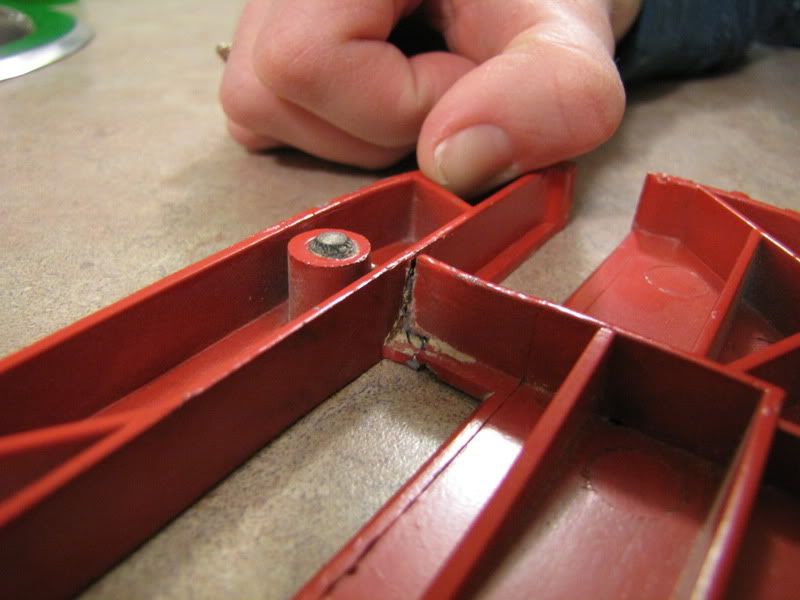

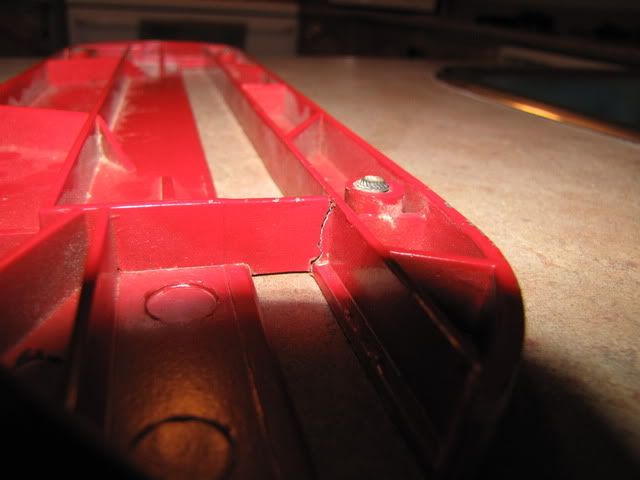

I was just cleaning off my tablesaw to put it away for the night and as I shifted the blade wrenches over a bit I heard a lound clang as my table insert hit the floor.It cracked right at the bridge piece that separates the splitter from the blade.

I am wondering if this can be fixed with some sort of adhesive or something. The good thing is that the crack fits nicely back together and leaves no edge that would cause any interference while using the table insert. I generally use zero clearance inserts but when cutting a bevelled cut I need this insert. I contacted black and deckerto find out about a replacement part and they want $60 plus tax and shipping.

Anyone have any ideas of how to repair this crack. I am thinking along the lines of JB WELD or some sort of very strong construction adhesive. The JB WELD seems to be more up this alley though.

I appreciate your thoughts and ideas.

Reply With Quote

Reply With Quote