OK, everyone. George nailed this one. I was getting tired of my waterstones and wanted to try something simple. I picked up a black and white (ultra-fine) Spyderco stones to try them. Here are my observations:

The ultra-fine was dead flat but the black stone was was out...way WAY out. I've been rubbing it with a coarse diamond stone, and it's getting flat...it will take a while.

I spent a couple of hours re-sharpening some chisels and planes. First I put them on my Tormek to fix up the edges and get a hollow grind, because that's what I like. I didn't bother to surface the wheel to the "finer" grit. I just took them off however they came. Then I took them to the ultra-fine Spyderco. It takes about ten swipes to completely remove the Tormek's coarse scratch pattern. Then I stropped it with Simichrome.

And the end result? Guys, these things are sharp, and I mean SHARP. Ridiculously sharp, actually. Not only that, this is by far the fastest I've ever sharpened in my life. Mind you, I wasn't just touching up my bevels. I changed all my LN chisels to a 30 degree bevel. That took all of maybe a minute on the Tormek...maybe 1 1/2 minutes if you count setup time. Then another minute to hone them on the Spyderco and maybe 30 seconds to strop them.

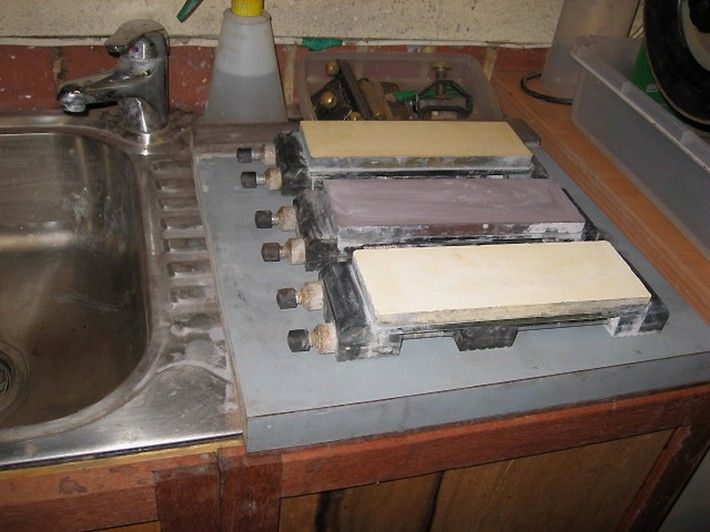

No flattening stones. No spray bottles. No sharpening juice all over the place. Do I have any gripes? Yeah. The stupid stones are only 2" wide so I have to sharpen my larger plane irons without a guide, using circular/figure 8 patterns instead of long strokes. This is really not a big deal, especially with the hollow grind. I wish they had a slightly wider stone though. I guess I can use the guide at an angle, but there's really no reason to.

Anyhow, you don't really hear much about these stones other than George constantly recommending them so I thought I'd chime in as a recent convert. The ultra-fine is the real deal. The black one is disappointing but I suspect I may not use it other than an initial flattening of the back of a chisel, and by then I'll have gotten the stupid thing flat

Reply With Quote

Reply With Quote