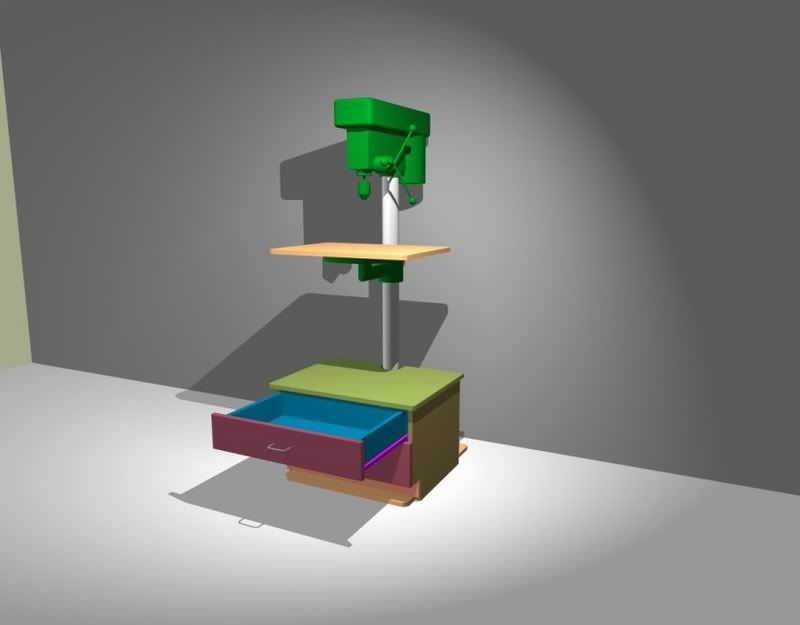

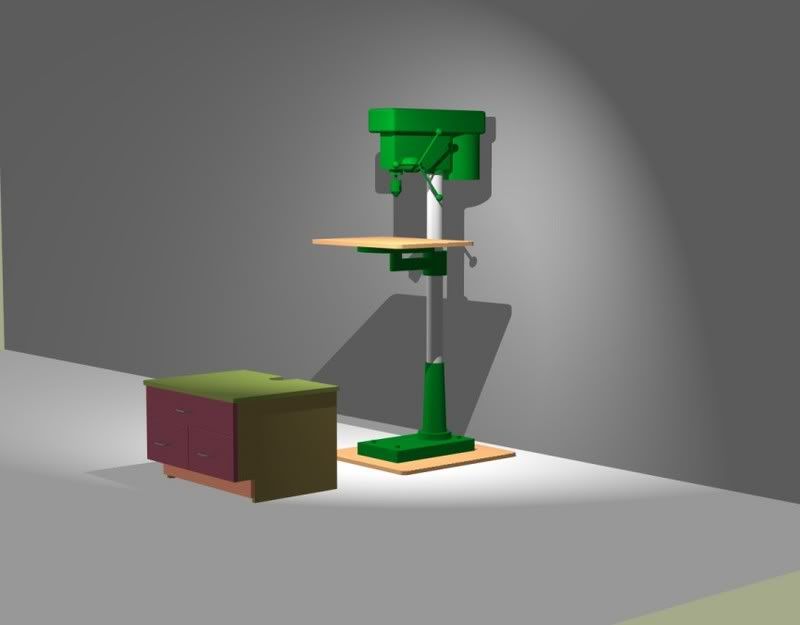

I am debating on selling my Griz free standing drill press and going with a bench top. I rarely use my drill press other than simple holes etc. Just thinking of the space needs for my shop. Wondering if anyone else has traded down and if they have had any regrets?

Reply With Quote

Reply With Quote