One of the pieces of the cabinet project we are doing is a "mormon pantry" (38" wide by 65" tall). My wife insisted on only 2 doors and only 2 panels per door. So I ended up with doors 18 3/8 X 65 9/16 with 3 rails. Needless to say one door failed within a week of use - the rails separated from the stile with the hinges. The doors were assembled using glue and dowels - it looks like we did not have sufficient glue and have reassembled with plenty of glue.

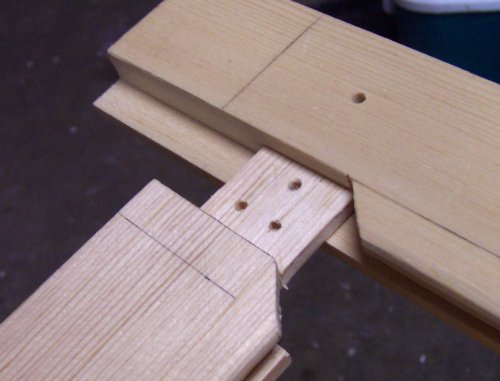

The construction was traditional - stiles full length of the door and rails between the stiles. My question is; is there any reason why the rails could not be the full width of the door? This would reduce the tendency of the joint to flex at the junction of the rail and stile.

If we have to re-frame the doors, what would be a better way to strengthen the rail/stile joint? I know screws are a possibility but with 3" stiles it would take long screws and possibly deep holes to use them. One of the feature of the project that we are most proud of is the fact that we have used no nails or screws (except of hardware mounting).

Reply With Quote

Reply With Quote