I recall seeing a thread a while back about shop made overarm tablesaw guards with integrated dust collection. I can't seem to find it by searching. Does anyone remember the thread well enough to point me in the right direction?

Thanks,

Andrew

I recall seeing a thread a while back about shop made overarm tablesaw guards with integrated dust collection. I can't seem to find it by searching. Does anyone remember the thread well enough to point me in the right direction?

Thanks,

Andrew

http://www.leestyron.com/

Here is a link to the Shark Guard.

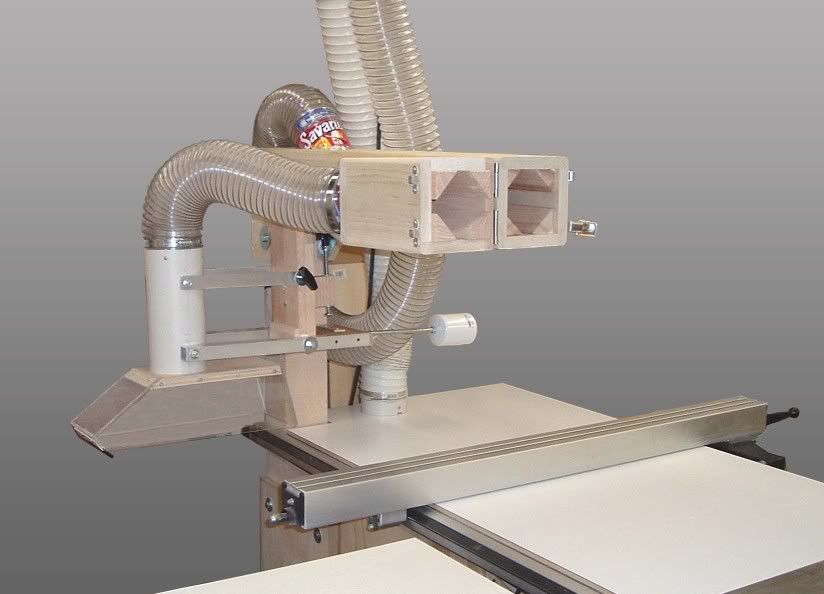

Here's a pic of my overarm dust hood. It works OK at capturing the dust, especially when working with MDF or melamine. However, I don't consider it a guard.

It should be noted that there are many cutting situations where the hood is in the way. Whatever you come up with, make sure it removes or swings out of the way easily.

If your interested in the plans, send me a PM with your email address.

-Jeff

Thank goodness for SMC and wood dough.

The coffee can adds a touch of class!

Nice overarm!

I've been trying to figure out a way, to hook up a 4'' hose to my PSI overhead dust collector. Jeffrey after looking at the plywood in the top of yours, I think I've may have figured it out. Thanks for the pics.

Norman, what I did for a 4" hook up at the OH pickup I made is use a 3" X 4" to 4" round adapter from Lowes (HD?) that converts the plastic rain gutter down spout to 4" S&D pipe. It works great!! You can set it to which ever orientation you prefer. I made mine the 4" width so that the plexiglass sides but up against the adapter. dscn2619.jpg I had a 22.5 degree elbow attached to the down spout piece on my first unit for the contractor saw. This is the newer one for the cabinet saw. It needed to be longer for the riving knife, so didn't need the elbow. Jim.

Coolmeadow Setters...Exclusively Irish! When Irish Eyes are smiling....They're usually up to something!!

Home of Irish Setter Rescue of North Texas.

No, I'm not an electrician. Any information I share is purely what I would do myself. If in doubt, hire an electrician!

Member of the G0691 fan club!

At a minimum, I'm Pentatoxic...Most likely I'm a Pentaholic. There seems to be no known cure. Pentatonix, winners of The Sing Off, s3.

Jim, can you show some other pictures of your setup?

Just so you all know, David saw this recently when he was here visiting family. Yes, here are some other views: This is taken from the left side of the saw. dscn2754.jpg

This is from the right side of the saw. dscn2755.jpg

These views show close ups of the three point attachment to the ceiling to keep the unit as stable as possible. DSCN2757.jpgDSCN2756.jpg

I built this using the instructions From this WoodCentral post. wwwdotwoodcentral.com/bparticles/overarm_guard3.shtml Just change "dot" for a "."Jim.

Coolmeadow Setters...Exclusively Irish! When Irish Eyes are smiling....They're usually up to something!!

Home of Irish Setter Rescue of North Texas.

No, I'm not an electrician. Any information I share is purely what I would do myself. If in doubt, hire an electrician!

Member of the G0691 fan club!

At a minimum, I'm Pentatoxic...Most likely I'm a Pentaholic. There seems to be no known cure. Pentatonix, winners of The Sing Off, s3.

Thanks Jim, I'll check that fitting out. I made my overhead from a bar clamp too. I copied it off a post over at WoodNet.

One thing I really like was the mustache I gave my hood using a standard door sweep from FrostKing. I probably should have put it on the sides of the hood too.

-Jeff

Thank goodness for SMC and wood dough.

Jeff- nice guard and photos! Looks like you put a bit of work into that.

Jim- I think I must have seen a previous post about your guard becuase that is what I was thinking about when I originally posted.

What material and thickness are you both using for your guards? What about compatible glues?

Thanks again guys,

Andrew

I had a setup similar to Jim's on my Craftsman 22124. It worked well but the hose had to be supported correctly or it would place too much weight on the guard.

I recently retired and my coworkers asked me what I would like for a present. I told them I was planning on buying a Grizzly G0691 and that a few bucks toward the purchase would be great. They surprised me with 2 - Grizzly Gift Certificates which completely paid for the saw, the mobile base and shipping. I added a Woodpecker lift and and Makita router in the extension table. My homemade router fence connects to the table saw fence when in use. I used a plastic garbage bin from Target for below the router dust collection. It has a hole on its front side which doubles as an air intake and allows easy speed changes. I built an outfeed table patterned after Jim Becker's plans, but with an old drafting table with its folding legs for the large extension. I got tired of messing with prototypes for the over blade dust collection and purchased a Saw Stop Blade guard. It easily connected to my Grizzly stock splitter. It works very well.

Would you be so kind as to send me the plans for this overarm table saw guard? I'm very interested. Thank you very much... Bob Barnes

rkbarnes@cfu.net

Bob, which plans are you talking about? There is information in my post for the plans on how to build the one I used to make mine.

Andrew, sorry I didn't make it back to this thread now over 3 years ago. I used silicone and screws, drilled and tapped into the 1/4" sides. I think it is plexiglass, but I'm not sure. Previous owner of this house left scraps behind and I used it. The top part on my is made from some PTEG scraps Ed, the original owner of ClearVue Cyclones was kind enough to send me to play with.

I need to add some of the brush material to mine also to keep it from marking the wood as it travels over during a cut. I used some "slick" tape, that works ok, but it tends to become loose and bunches up, causing the head to catch on the front edge of the wood as the cut is started. Jim.

Coolmeadow Setters...Exclusively Irish! When Irish Eyes are smiling....They're usually up to something!!

Home of Irish Setter Rescue of North Texas.

No, I'm not an electrician. Any information I share is purely what I would do myself. If in doubt, hire an electrician!

Member of the G0691 fan club!

At a minimum, I'm Pentatoxic...Most likely I'm a Pentaholic. There seems to be no known cure. Pentatonix, winners of The Sing Off, s3.