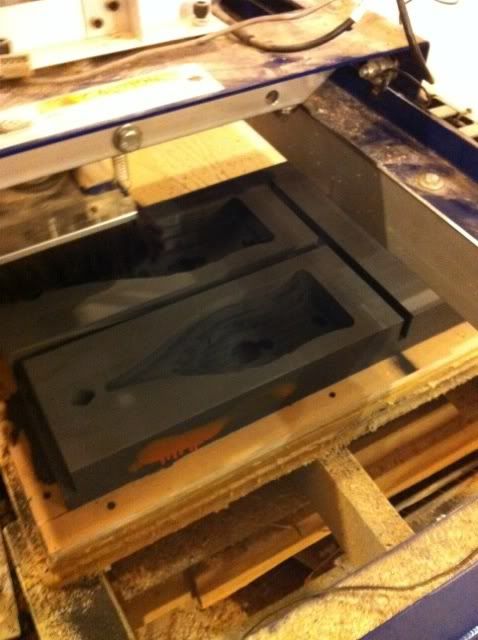

I have been doing work for a glass blower and this time I have to cut the mount out of a 24"x13"x3" block of graphite (it only costs 1500.00) I cut it on my cnc router but I need to saw the parts apart and cut for thickness. last tiem I tired it on my bandsaw it kept bogging down. but I think the blade was slipping since it took a bit to get back to speed. the stuff cuts pretty easily for the most part.

Reply With Quote

Reply With Quote