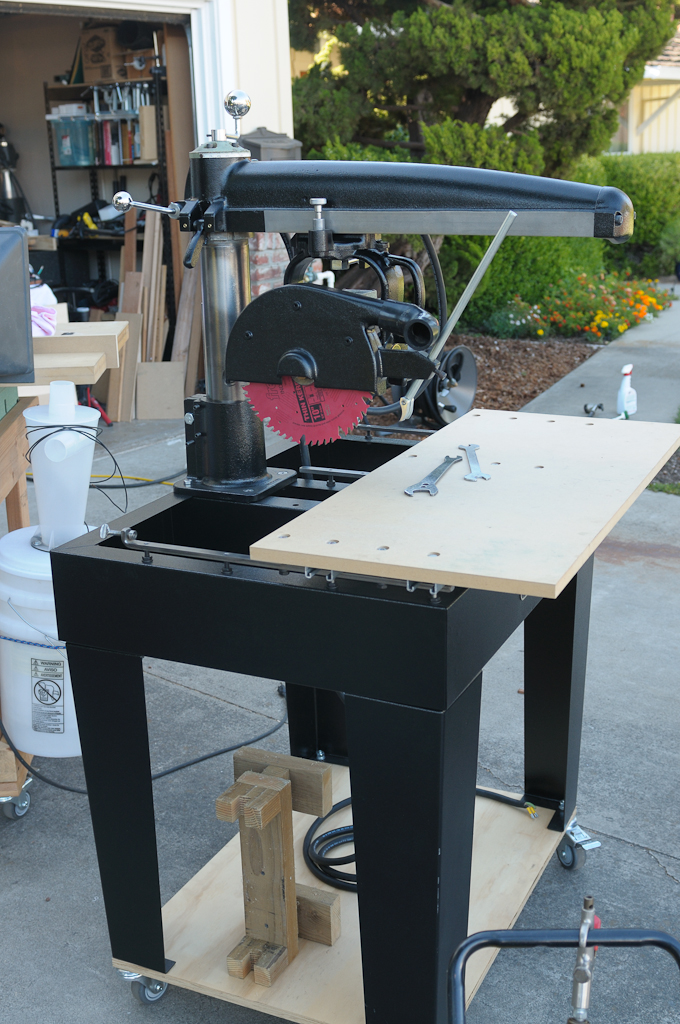

So about 2 yrs ago I bought a Craftsman RAS at a yard sale for a whopping $5

I knew I didn't really have "allot" of use for it, but come on $5

So in the past 2yrs I've used it on 3 major projects.

1st was a retail tenant improvment

2nd was some custom shelving 14" deep and mitered.

3rd (tonight) is a commission for 100 display cases.

Well tonight I fell in love with this RAS all over again. Breaking down 312 liner ft of 1x material into 12" and 11.5" pcs

I just wanted to give a shout out to all you RAS haters(or to be more PC, all you RAS disapprovers

)

Reply With Quote

Reply With Quote