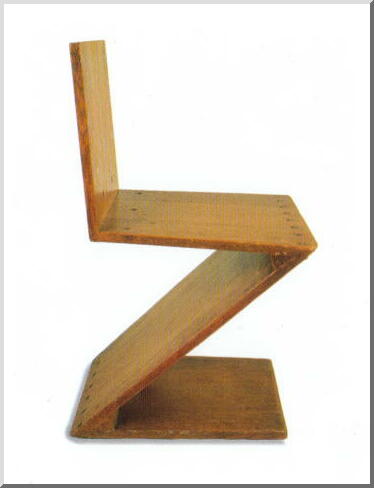

I have always been fascinated by this chair by Gerrit Rietveld, a design he produced from the 1930's. It's still being manufactured today, at least reproductions of it.

As far as I can research, the chair does use mechanical fastener, though I'm not exactly clear on the method. Here's one description that I found:

"This remarkably stark design consists of only four rectangular sections. The seat and back have been dovetailed together, and the seat and base reinforced with two triangular wedges. The brass nuts and bolts holding these wedges together represent one of the few times in De Stijl design where the hardware became part of the overall decoration. This system of joining belies the complex construction of the piece: the nuts and bolts must pass through each of the panels to produce the necessary strength for the cantilevered structure. "

Regardless, I wonder with the advent of modern adhesive, is there a way to build this without mechanical fastener? Perhaps with some sort of box joint technique, there'll be enough long grain contact for the adhesive to hold?

Reply With Quote

Reply With Quote

This is the Retveld Chair on the cover...

This is the Retveld Chair on the cover...