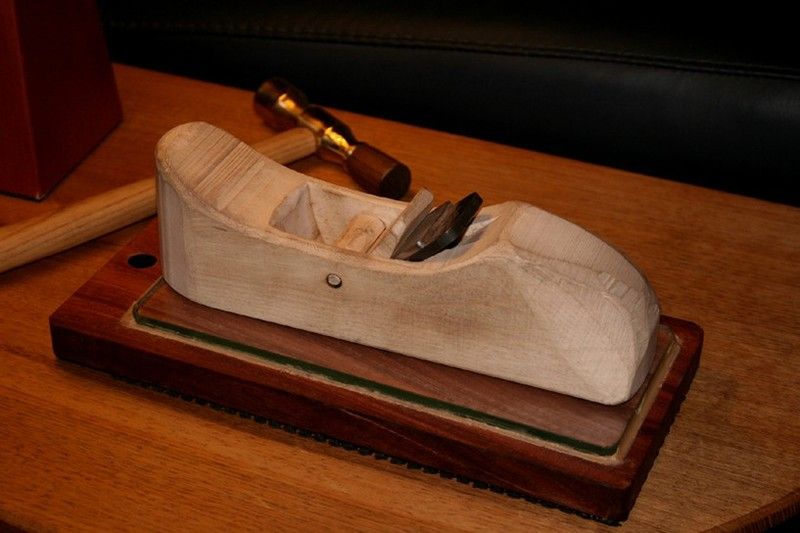

I'm a noob when it comes to hand tools and got a veritas plane because I want to build a shooting board. The set screws to keep the plane blade from shifting, am I supposed to lock tite it once I get it where I like it?

I just finished trying to set one up and am super impressed with the shavings this thing is producing and I haven't even sharpened it yet.

Gonna practice sharpening some junk plane blades before attempting to sharpen the one that came with the plane.

thanks

Reply With Quote

Reply With Quote