I've done some work with hickory and find it really challenging to work with. It is very hard wood and tends to give off really nasty slivers. It does have interesting grain and color and once you get done with it it's durable.

I've done some work with hickory and find it really challenging to work with. It is very hard wood and tends to give off really nasty slivers. It does have interesting grain and color and once you get done with it it's durable.

Well I got my plans Saturday. I must say that this will be a difficult project to take on, but that's ok. I'm up for the challenge. I have always nailed everything together. The biggest change for me to accept is that I wll now have to glue this entire chest together, and the joints must be created with rabbets or tongue and groove type stuff. I am going to attempt to draw a solidworks file of this thing so that I will have a better understanding of how it fits together. I'll post some progress of the drawing as I go along.

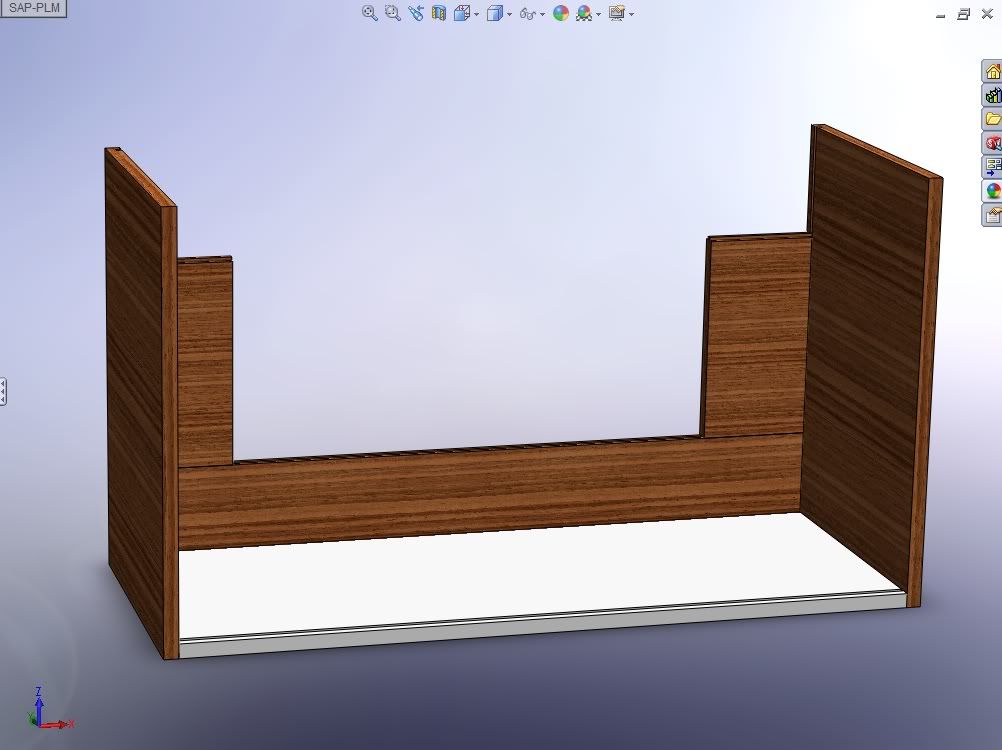

Here is the first of the design progress pics. This is the bottom, The lower rear panel, the two sides, and the two rear stiles. Pay no attention to the grain direction. Solidworks adds it in whatever way it chooses, and while there is probably a way to properly orientate it, I'm not sure how.

The bottom is white because I initially wanted to use plywood there, but I feel like the edge showing issue is gonna cause me to use walnut there too.

If you don't mind driving to Huntsville, check out the CL. I've seen walnut several times there. Just across the GA State line is a place called Eutree. They appear in the Birmingham CL all the time and they look like they have quite a selection and pretty good prices.

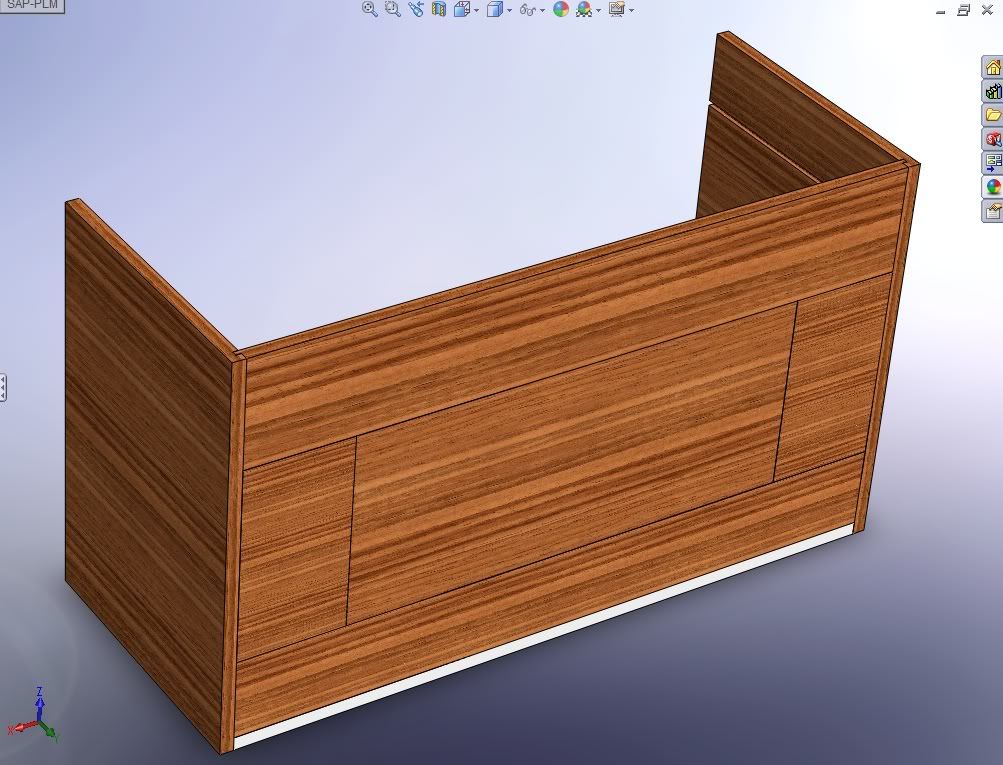

Here are a few more. Now I have the center piece in the back, the upper rail, and the notch modeled in that will be the location for the floor of the upper compartment.

John,

Check out this Ma and Paw opperation I found her on the bay She`ll gladly take orders per your spec or bill of materials. She can be contacted through the bay..I have no affiliation with seller .She advertizes good prices..

http://www.ebay.com/sch/deer56hunter...&_trksid=p3686

More about this seller world page

http://members.ebay.com/ws/eBayISAPI...d=deer56hunter

www.machinistchest.com

...MC

Last edited by John Miletta; 07-23-2012 at 1:12 PM.

Another good wood option would be Mesquite. Dark in color, machines well, and is very durable.

I think quartersawn white oak is worthy of consideration. If the chest is constructed well, it won't look common - even if made out of pine boards (which is not an altogether bad choice either!).

I also submit that if you can, make it out of 4/4 boards planed to 3/4". Nominal 4/4 is the most common rough lumber dimension, and as such is easiest to find and often cheaper than even 1/2" stock.

If you want it dark, then walnut or cherry are great choices. Cherry will look pink at first, but will turn deep, brown/red within months or years.

The question I have is though you say you are a machinist, you don't say anything about your woodworking experience, skills, and tools. Your questions tend to indicate they are minimal. That will make a big difference in the quality and durability of your chest. It could be quite heavy depending on contents- I know my grandfather's chest was. Some machinist skills, especially precision and adherence to tolerances, translate well to woodworking, but few machines, hand tools, and construction techniques do.

My suggestion is to first make a prototype chest from poplar or pine, before making expensive walnut dust.

Alex's in Lafayette will probably have some walnut that wide. And he can plane it to your finished thickness for you, at a fee. I am sure there are other mills or suppliers closer but this is the only shop I know in the vicinity. Ask for Curtis if you call. His number is 334-864-8514.

Have you started to cut the wood yet? It's been 5 months.

Trouble is, you only want to do it once.

The trick is to follow the plans to the letter, measure carefully, and make your cuts right-on.

I used cherry. Got the plans from Shop Notes. Took about 3 weeks of pretty steady work.

Here are a bunch more pics of the process.

http://s938.photobucket.com/albums/a.../Tool%20chest/

100_3066.jpg

Last edited by Myk Rian; 07-23-2012 at 6:07 PM.

Never, under any circumstances, consume a laxative and sleeping pill, on the same night

If you are still looking for walnut, I have plenty.

Myk, that is a gorgeous chest, well done...

not matter how much time we estimate on small projects, multiply by 3, which is prob. accurate.. Considering the detail, 3 wks, IMO not bad...

this demonstrates the incredible time saving use of jigs, or pre jigged machines when you do a certain procedure over and over. But when ya make ONE of something, well... ya keep wondering how days turn into weeks!