Hi George

I figured that a ogee would be impossible to do with a single router "cut" having glued the box together, that is, the two sides would not fit. Anyway I decided that I preferred the simplicity of a straight line ... and later I think that you will agree with me.

OK, so the box needed to be cleaved in two. It always looks straightforward when looking back, but this was a reasonably complex task.

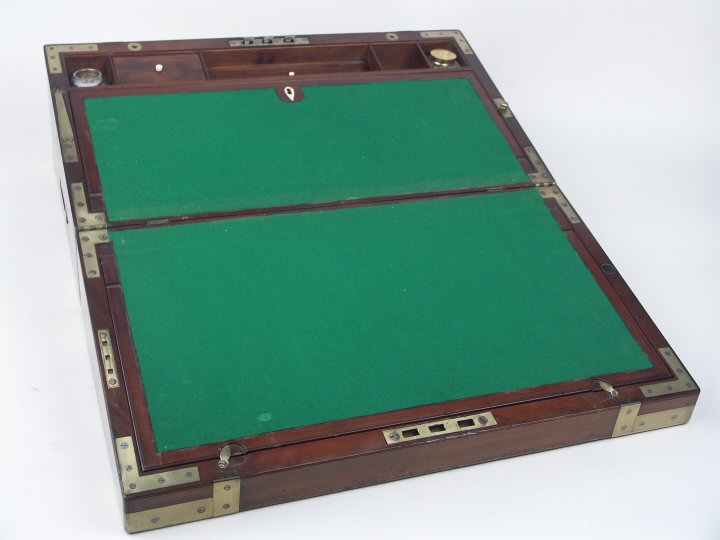

The inspiration for the design came from a campaign writing desk ...

I've been wanting to build one of these writing desks for a few years. Perhaps you have been as well. If so, my experience may help you a little.

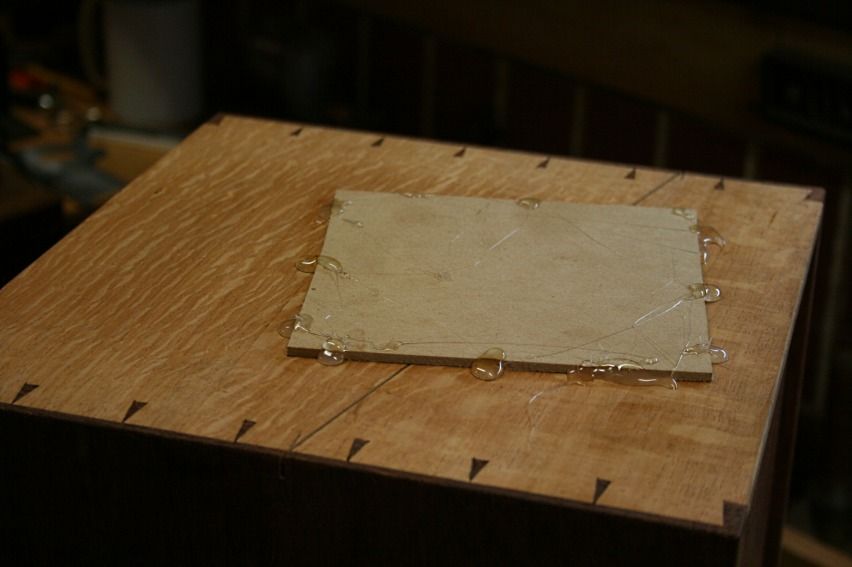

The box had been glued up at the last post to ensure that the sides remained coplanar after sawing off the lid. Now it was time to do this. A template for marking the sides was made out of thin MDF ..

Sawing on the bench was difficult owing to the extra height created. I could have done with a platform, or platform shoes!

I have a guide that does triple duty: one side is angled for siding dovetails, the other is at right angles for a dado plane. I added a few rare earth magnets to the latter for a saw ...

... and brought out "The Beast", a 28" x 5" Disston mitre saw.

The sides of the box were sawn until just through the side thickness.

Before sawing the front and back I hot glued scrap MDF over the sides to hold them in place ...

A new guide for the front and rear sides was quickly made up on the tablesaw. This was to maintain the angle of the side saw cuts.

No magnets, so you just need to hold the saw against the fence.

I did not saw all the way through on the first end, stopping just short. Then completely sawed the second end, before returning to finish off the first end.

The result was pretty good. There is a tiny amount that will benefit from being lapped smooth. That is for tomorrow.

A side ...

Rear ..

Front ..

Sides together ...

And a preview of what I am after ..

Regards from Perth

Derek

Reply With Quote

Reply With Quote