I have gotten shiny surfaces in all kinds of woods,hard and soft. If you show a surface magnified enough,you will see atoms lined up and ask what's shiny here? No problem finishing said surfaces either. As for gluing up,it was determined ages ago that a smooth wood surface gives a stronger bond than a toothed one(contrary to what was thought in past centuries).

I can't duplicate what you're seeing without looking your planes, seeing how they're sharpened, and how they're set up.

I do remember very vividly one experience in our shop. Don and I were packing up for a show and, our former partner, Bill was supposed to be bringing the first of the strike block planes we were offering. It took Bill longer than he thought or we expected to arrive with the plane. Don wanted to make sure the 40 degree bedded plane worked as expected and had a shooting board waiting. When the plane finally arrived Don set it for a very light cut and took a a shaving on end grain. I heard him grumble and say the plane wasn't sharp. Don quickly resharpened the iron following the cutting geometry it came with. It still didn't work properly and Don felt like he was having to force the plane. Then Don looked at the wood and saw it was burnished. He checked the iron and found Bill had sharpened it with a 30 degree bevel. Ten degrees of clearance angle wasn't enough for even very light shavings in end grain. Don reground the iron and honed at twenty five degrees. The plane then worked as it should and the burnishing on the end grain disappeared. The reduced deflection of the twenty five degree iron bevel and the increased clearance angle made a huge difference in the performance of the plane.

If you're using a closely-set blunt cap iron on a plane with only ten degrees of clearance and not seeing a difference when the clearance is increased to twenty degrees I'm at a loss as to what you may or may not be seeing.

Again, just thinking out loud here and what you're explaining is making sense in my mind. Without testing, what I think I think is that the chipbreaker 'trick' doesn't work as well with a medium shaving. Thick shavings can be ignored because we're traversing the grain.

Assuming you're working with hardwoods and your jointer (or try) is set to take a relatively thick shaving, might a higher bed angle be an appropriate compromise? A 47-50 degree bed might make up for not having just a glint of blade past the breaker?

What's happening on the subcellulair in the wood is completely beyond me. I'm just your average Joe, puttering along in my garden shed. The surfaces I get with the chipbreaker close to the edge are fine. They look very nice and take glue or finish just fine. I don't use stain in my work, so no idea about that. I wonder if you weren't setting the chipbreaker too close, Larry? You're all the time talking about 4 thou for the chipbreaker, but I find 8 to 12 thou a much more desirable distance when taking relatively thick smoother shavings. Maybe that's the reason you got a burnished surface? (just a theory from me).

I think we all agree that tearout looks like crap and that tearout is a common occurence when using the common 45 degree double iron planes. These planes are nowadays all over the place and can be pickup in decent shape for 20-40 euro. Wooden double iron planes are even more common overhere and are usually to be found in the sub 5 euro category. Most woodworkers with an interest in handplanes have one of these. So what would you advice when someone like that asks how he can avoid tearout? Would you advice him to stand in line for one of your planes, and use the ROS in the mean time? Or would you advice him to buy a LV bevel up smoother at 219 dollar, maybe even with an extra 50 degree blade at 35 dollar? Or would you teach him how to use the tool he allready has?

I''l repeat, chipbreakers work, it's not very difficult to use them and are highly practical in every day use. Just like all other woodworkers since the late 18th century, until the demise of handtool woodworking, discovered allready for themselves.

I don't doubt it Sean.

No doubt you're right about hair :-)

Joyce, in the Encyclopedia (the Alan Peters edited/updated version), says cap iron from a 16th (rough work) down to a 'hair's breadth.' A hair's breadth is pretty close but the larger takeaway is that it's being moved around. At least it is if you don't have a plane set up for every stop along the way, though I grant most folks would never have a smoother set up at a 16th with an accompanying heavy camber, yet if you only have a few planes and are working on a budget and extra iron is cheaper than a whole new plane.

Last edited by Charlie Stanford; 01-02-2013 at 7:35 AM.

Kees,in the museum situation,everyone spent a significant amount of time trying to work out how they did things in the 18th.C.!! Like,squeezing threads into wrought iron instead of cutting them with modern dies. The threads very often had chunks fall apart from the silicon inclusions when cut rather than squeezed into shape by old fashioned screw plates which did not cut,but formed the metal.

Nice bit of historical information George. I love that.

Since we spend some time on the chipbreaker study I have dabbled a bit in tool history myself. It's fun. Just searching when the double iron plane hit the Dutch market led me along curious paths in google books, old newspapers and museum websites. BTW, The Dutch were pretty late with the double iron plane. Partly because of the rich tradition of single iron planes from the guilds period. And partly because at that time, The Netherlands were one of these countries where "everything hapens 50 years later". The earliest mention of double irons in planes were in the books from Peter Duesing who made planes for the Dutch market but was living and working just over the border in Anholt, Germany. 1837 it was. There was also a book from 1856 with an article about handplanes. The writer describes the usual kit of foreplane, jointer, double iron plane (smoother). Here he describes how the capiron is used to prevent tearout in difficult wood. But he also describes how you can get the same effect in the jointerplane (obviously a single iron plane) with a backbevel.

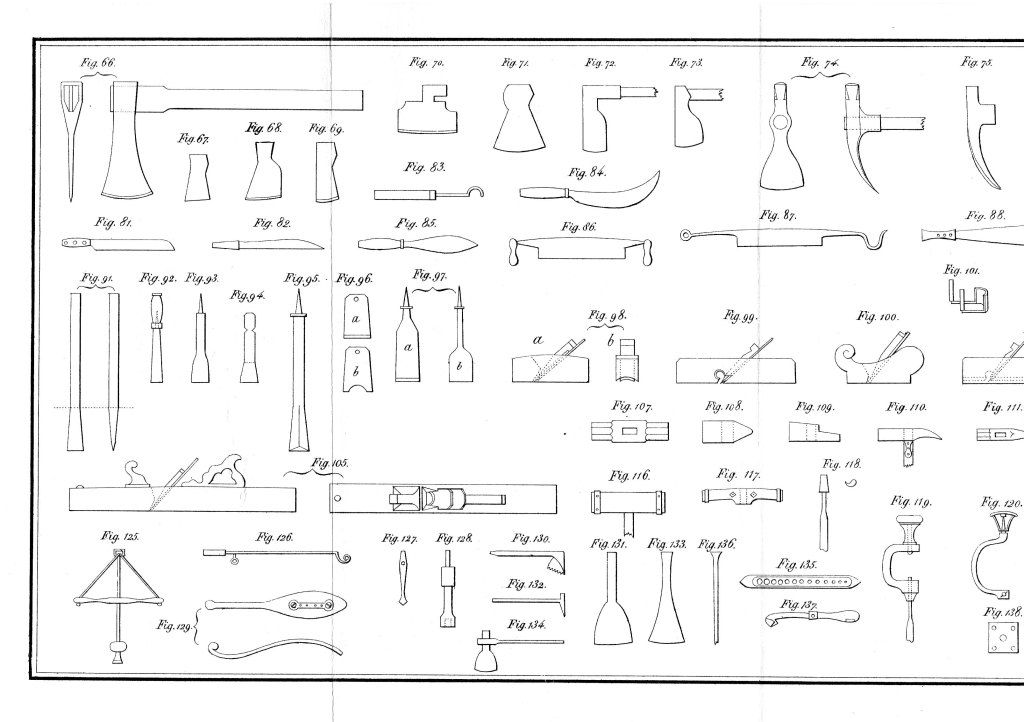

Here is a plate from a shipwrights book from 1859. You can find the jointer wich is obviously a single iron plane at 50 degrees or so, and a double iron plane at nr. 98. That one is a hollowing plane, but the text describes a similar smoothing plane.

Interesting that a Dutch chisel recovered from the 16th.C. shipwreck at Nova Zembla(sp?) had nice,beveled edges,looking much(in the blade) like a short,Shark brand modern Swedish chisel. Blade was slightly tapered in width towards the handle end. Likely to help in cleaning out corners(my theory). Handle was like an 18th.C. English handle.Octagonal,slightly tapered.

Warren showed pictures of mortise chisels that were made that way, also. It would be a nice feature to have.

This one I suppose?

https://www.rijksmuseum.nl/nl/search...#/NG-NM-7667,3

That's the one.

Did they know what it's made of? Is it similar to late 18th century steel?

No, it sais just "iron and wood". I guess they are more knowledgable about paintings.

It is a big chisel, 4.2 cm wide at the cutting edge, that's about 1 5/8".