My 25+ year old kitchen cabinet doors (white Formica with oak trim top and bottom) have finally worn out their welcome, about a decade ago. It seems Mission Style is all the rage today so I thought I'd go with that.

All the cabinet doors I've made so far I've done with CMT router bit sets and they have all withstood the test of time. All rails and stiles start at 2-7/16" wide and once routed create a 2" wide effective width. That makes measuring a lot easier.

CMT has a Mission set that I don't particularly like for making Mission Style doors.

It looks like they only require 1/4" plywood panel for the center panel. Every cabinet door I've handles with 1/4" panel has seemed very cheap. What I was thinking was cutting the 1/4" dado into the rail and stile and then cutting a 1/4" rabbet into the back of a 1/2" piece of wood or plywood for the center panel. I think I'd also cut the dado deeper where the rail and stile meet and maybe cut a shoulder for additional strength.

What I was wondering:

- Should I rough cut the rails and stiles 2" or should I go wider? If so, what width?

- I was thinking mahogany for the rails & stiles and figured maple for the panels. Does anyone make 1/2' plywood with decent figure in the maple veneer? Or should I stick with solid wood to get that appearance of depth?

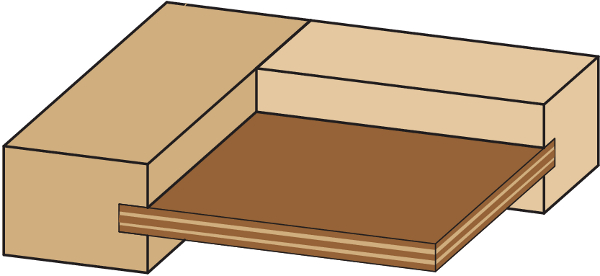

- The drawers will only be 6" high. If I go larger than 2" for the rails and stiles on the doors, should I keep the same size for the drawers, leaving a very narrow panel in the middle, or should I make the drawer rails & stiles narrower?

Reply With Quote

Reply With Quote