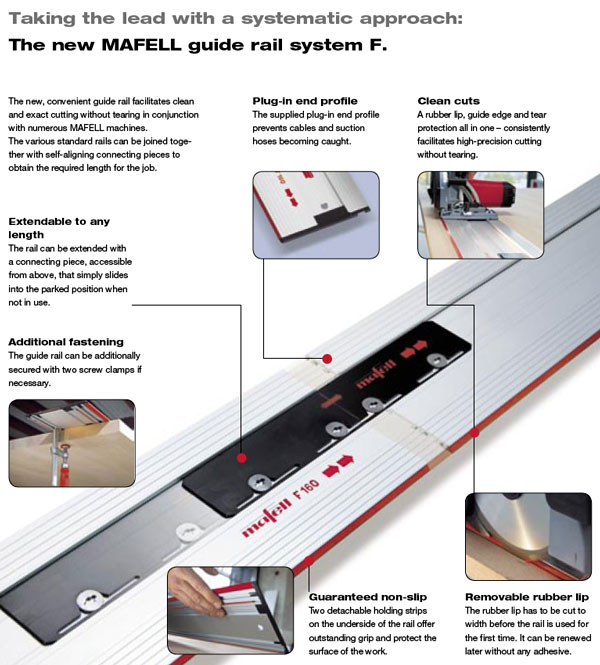

With the Mafell/Bosch rails, there's a substantial connector.

It would seem to me this type of connector would be superior to the two bars you see in other brands.

I saw a video of the Betterley connector aligning Festool rails and it worked perfectly.

The Betterley claimed to align two tracks regardless of the condition of the ends. So if they were banged up or out of square from the factory, it didn't matter. Seeing the Bosch connector in action convinced me it was better than the two bars method.

Reply With Quote

Reply With Quote