I started a few weeks ago on a mesquite desk for a fellow Ag. We went back and forth on deciding on a walnut slab top, but the costs were pretty rediculous to get a slab shipping in, so we ultimately settled on a mesquite desk, given that I could get some nice mesquite from South Texas cheaper than walnut from Idaho, Pennsylvania or Oregon.

First was to find a bookmatch set of boards I could make a 60" x 30" desktop from:

Then to level each board and thickness them. One was about 1/4" thicker than the other, and I don't have a machine large enough to level them, so I made a few rails with a bridge for a router to move back and forth on. I put an end mill bit on, and went back and forth with the router on the rails removing about 1/16" at a time. I don't think my garage has ever been dustier, but it worked.

Then it was time to epoxy the cracks. Just some two part epoxy with a few drops of a dye to blacken the epoxy.

Glued together:

To keep the width at the middle where the boards bowed in, I cut them so they had a gap I could fill with some inlay.

Inlay (I just found some other mesquite that had a similar curve in the grain, bookmatched that, and then inlaid it into the gap.

Full slab with gap filled

I then inlaid a couple of cocobolo butterfly dovetails across some cracks for accents and stability against the cracks spreading any more:

Dry fit testing the framing:

Raised panels inset for fitting testing:

About all that is left is sanding down the top, making the drawers, and finishing everything. I got the lower cabinet panels oiled, then glued up the lower cabinets.

Then once glued up, I sanded the new joints from the glue up, the re-oilled everything to match:

I then cut the hardware for the mid panel. It is bed hardware that I adopted to work on the front panel, two hooks that mount on each side of the mid panel that slide into plates inset in the cabinets.

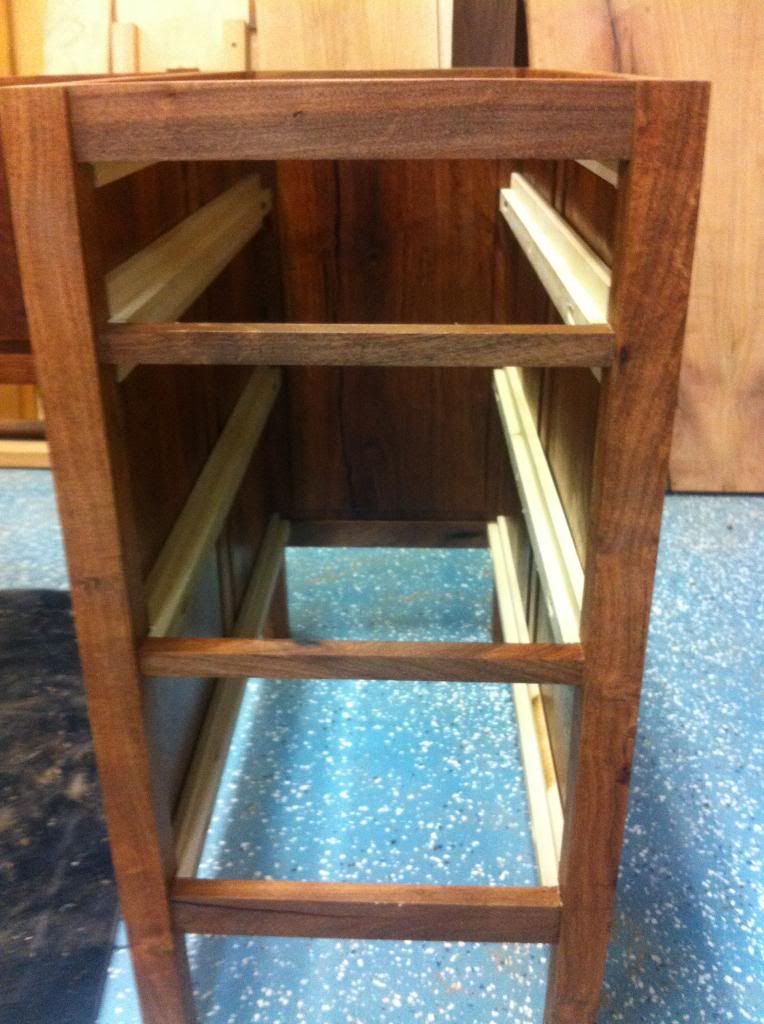

The I cut up the runners and spanners on the lower cabinets. The drawers are going to run on waxed runners. There is about 3/32"-1/8" gap between the drawer height and the runners, so it will be pretty tight against the drawer being sloppy.

The dovetails on the drawers are cut, and I've got the bottoms for the drawers made up. I am going to add some slots in the sidewalls of the top drawers to put in removable dividers parallel to the drawer face. Once I get the drawers done, it will just be lots of sanding to finish the top. The finish schedule is boiled linseed oil and waterlox.

Reply With Quote

Reply With Quote

Lori K

Lori K