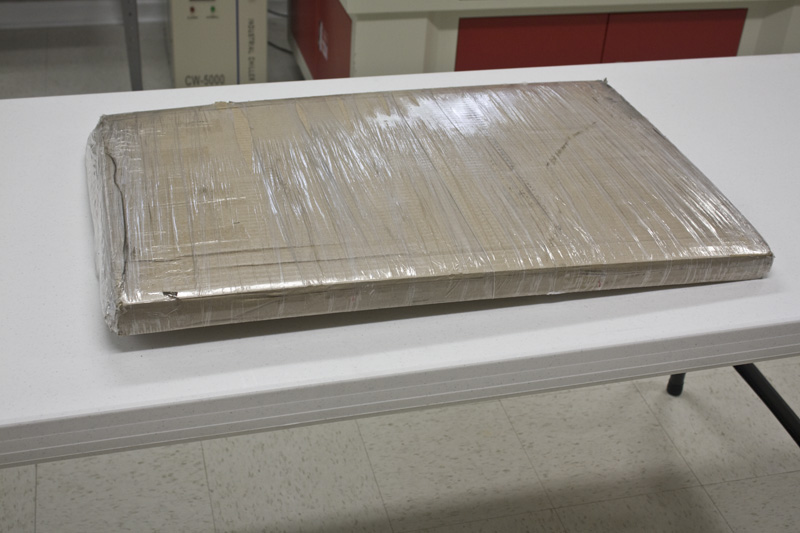

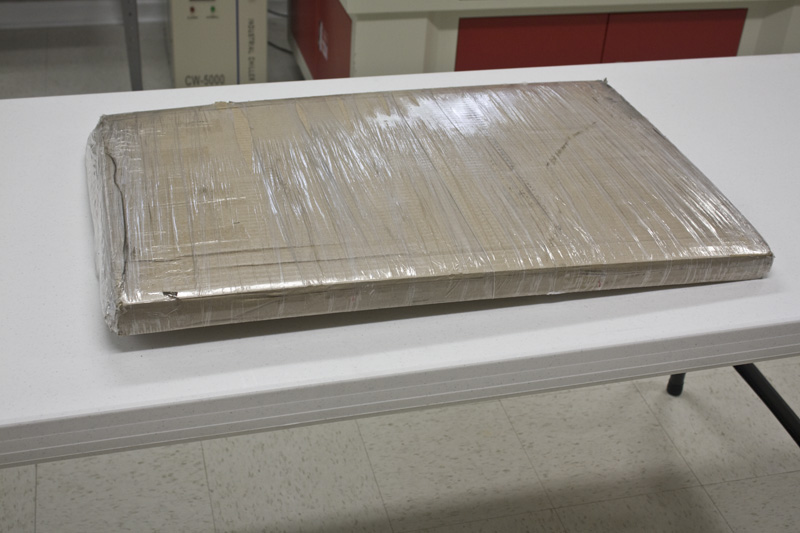

What would you do if your 12 sheets of 1/8" x 20" x 30" baltic birch came like this. I dont see the need to unwrap it

It gets worse if I pinch that back right corner down to the table.

What would you do if your 12 sheets of 1/8" x 20" x 30" baltic birch came like this. I dont see the need to unwrap it

It gets worse if I pinch that back right corner down to the table.

Rabbit RL-80-9060

Roland SP-540i

Graphtec ce5000-60

Graphtec fc7000-100

Happy HDC2-1501

Juki 1541s

This is what I use to cut almost all of my plywood, warped or not.

HOLD DOWN TABLE.cdr

The base is 3/4" particle board 32" x 20" it has a 1/8" x1" notch cut out of it where it slides over the x axis ruler on my laser. The red piece is a 1 1/8" x 3/4" x 32" board with a 1/8"x1/8" notch out of it. To use it I slide the piece of plywood into the notch in the red piece and use spring clamps to hold the other end. On mine the spring clamp goes around the bed of the laser as well. When working on smaller pieces I use a few half inch screws and washers to hold the far end down. With this set up you are cutting directly on a solid surface so the bottom side of what you are cutting will have damage, but not as much as if you were cutting directly on a solid metal bed. If you build a set up like this don't bother making it nice. It is disposable it will end up full of laser marks if you use it for cutting.

I have also built similar set up that used a honey comb bed and allowed air to flow underneath.

Universal M-300 (35 Watt CO2)

Universal X-660 (50 Watt CO2)

Hans (35 watt YAG)

Electrox Cobra (40 watt YAG)

Glass With Class, Cameron, Wisconsin

I'm not at my computer with corel on it, but your saying you can pull down a sheet that is this bad? Is this a common problem buying sheets this large? Suggestions on sizes to buy in the future would be appreciated.

See this is new to me since I just recently bought my first laser, and I bought this wood to make a few 3d puzzles.

Rabbit RL-80-9060

Roland SP-540i

Graphtec ce5000-60

Graphtec fc7000-100

Happy HDC2-1501

Juki 1541s

I often have sheets that when you push one end down the other end is 4 or 5 inches up on an 18 inch wide piece. I store my sheets flat with about 160 pounds of brick piled on them to keep them flat. On dry days in the summer and all winter long my sheets lay nice and flat but on a humid day they cup and curl like crazy. I use one side veneered hardboard so plywood or two side veneered hardboard shouldn't be nearly as bad.

I don't know it it is common or not. I buy full 4x8 sheets and cut them up myself.

Universal M-300 (35 Watt CO2)

Universal X-660 (50 Watt CO2)

Hans (35 watt YAG)

Electrox Cobra (40 watt YAG)

Glass With Class, Cameron, Wisconsin

Welcome to the world of laser birch ply Dennis, size makes little difference. If I really must use BPly then I use a selection of NdFeB magnets to hold them down. Wait till you hit some horrible stuff in the core and it doesn't cut after spending an hour on a job, then it gets really annoying!

cheers

Dave

You did what !

Dennis;

Tough to find perfectly flat BB in that size. I use a setup similar to Joe's and laser pieces as big as 30 x44". the piece gets framed once done so the warp is eliminated. Neo mags work well if you have a steel table. Also easy to make a adaptable table using 1/2 BB or mdf base and a bunch of steel 1" washers. Stack them 4 high, countersink the top one a bit and fasten where needed to the base with flathead screw-then neo mags have a grabbing point wherever needed. Arrangement can be changed easily to fit the job.

Best Regards,

George

Laserarts

magnets.jpg

This will give the mag enough power to hold. Choose top mag above material to suit nozzle clearance

best wishes

Dave

You did what !

Well my bed is one of those that looks like a car radiator on its side. I would say I could get a slab of steel for free, but the shop I worked at for 40 years let me go Monday.... So I may go to the hardware store tomorrow and get some mdf or particle board and just screw the plywood down to it.

Rabbit RL-80-9060

Roland SP-540i

Graphtec ce5000-60

Graphtec fc7000-100

Happy HDC2-1501

Juki 1541s

Honeycomb then Dennis? you can get bar type Nd mags that can be pressed into the honeycomb cores, that may be enough

cheers

Dave

You did what !

So many variables....was it in a lumberyard unprotected and already picked through?

what grain direction was it cut in?

Is it Genuine Baltic Birch or Chinese?

Was it in the sun for a period of time?

Have a Blessed day,

Michael Kowalczyk

Laser-Trotec Speedy II 60 watt with 9.4.2 job control and will soon upgrade to JC X

Corel Draw Suite X6, FlexiSign Pro 8.62, AI CS3 and Lasertype6

CNC Routers-Thermwood model C40 with 4th axis. Thermwood Model 42 with dual tables and dual spindles with ATC for high production runs,

ArtcamPro 2010_SP4, EnroutePro 5.1, BobCad v21 & v24, Aspire v8 and Rhino 5.

FOTC link

http://www.sawmillcreek.org/friends.php?cp=210&lp=0&t=0&q=

Ordered online. Haven't unwrapped it yet.

I sent them a email and the same pic and asked them if that was to be expected for every order.

Rabbit RL-80-9060

Roland SP-540i

Graphtec ce5000-60

Graphtec fc7000-100

Happy HDC2-1501

Juki 1541s

Dennis, What you have is unbalanced panels. This is very common (more so than naught). I also cut a lot of this material and found that a few lengths of 3/16 cold roll holds it down well and clears the nozzle. I am running the same laser as you. Also rare earth magnets hold the plywood well onto the iron honeycomb but a few lengths of steel along the edges has always worked well.

Doug

For all that I know there is so much more to learn.