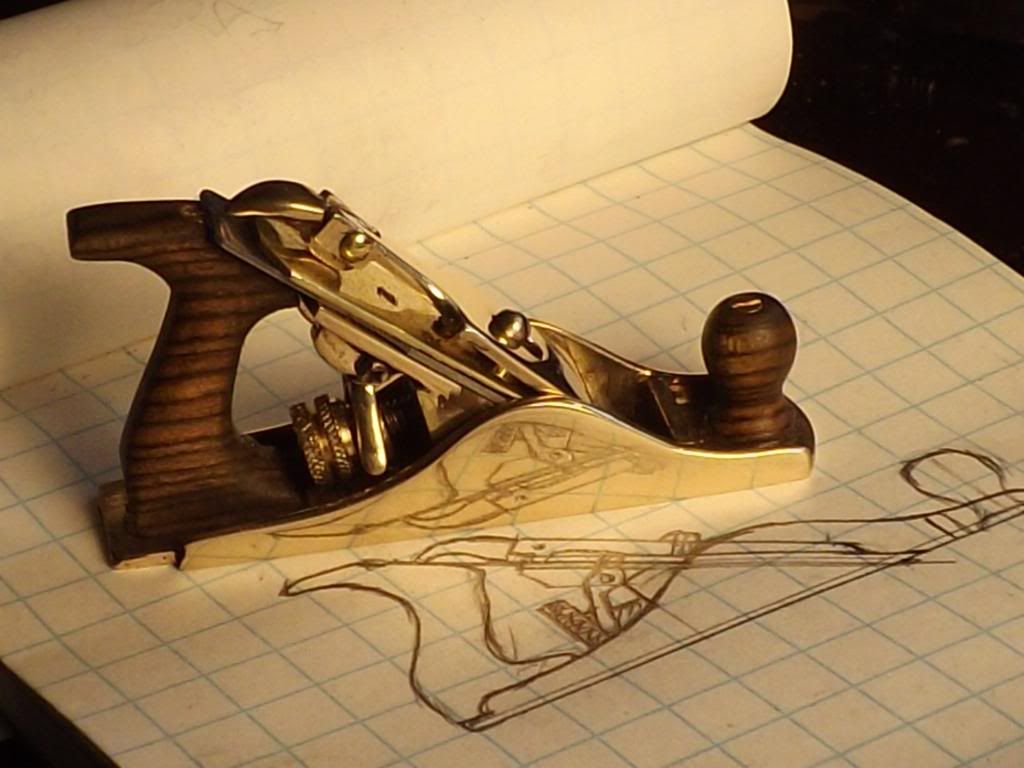

Please just call me Max, when ever I am called Maximillian I'm being scolded lol but if you would rather call me Maximillian its cool too you've earned by providing me the kid in a toy shop feeling. I really like how you intended to make hammers and ended up with tool art, but hey everything you make is art and still usable which makes it even better. I know you may not have a cut and dry answer but which is your favorite one?

Reply With Quote

Reply With Quote

)

)