This project got started about 2 months ago when I went to a local custom home builder and picked up 200-ish bf of Walnut.

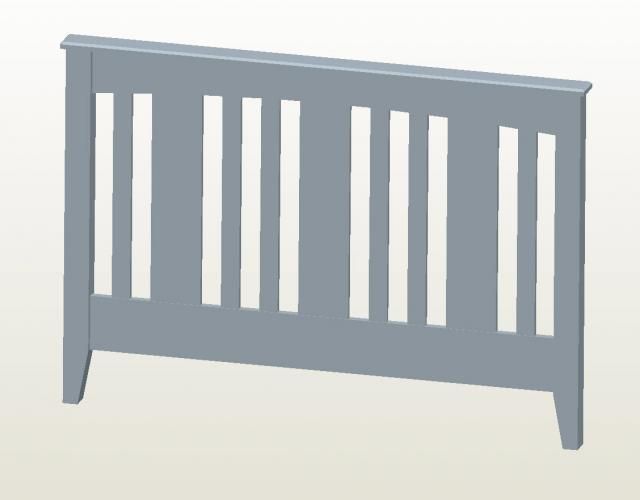

Below is a poor screen shot of my design for the crib, a pseudo A&C style with pointers taken from other designs I have seen. I have it all laid out in CAD with all joinery, makes working and layout very straightforward. The Crib also will convert into a Toddler Bed and Full-size bed, being loosely based on the Wood magazine plans.

I started by gluing up the legs with 3 laminations of 3/4"+ walnut, unfortunately I couldn't find any thicker stock to make the legs out of a single piece.

And the glue-ups, I need 6 legs, 4 for the Crib and 2 for the Toddler bed.

That is as far as I got with the legs, they are now waiting for final jointing/planing/dimensioning as I got started with the Sides.

The sides are made up with 7/8" bottom and top rails, 5/8" slats and a 3/4" cap.

First started with getting all the lumber ready. For the slats I got some of this walnut that is 7 3/4" by 3/4" thick that I am ripping down the glue seam in the middle to end up with 2 2" wide slats. Some of it had water/fire damage from the shipping department fire that it was in, but it hasn't given me any issues thus far.

I got to use the new Crosscut sled I built, square to within 0.0000125"/inch of cut, not too shabby...

Everything laid out to see what it would look like. The walnut is both kiln and air dried, so I decided to use this as a design element. The red, air dried material will be the rails and the kiln dried, drab grey, will be the majority of the slats.

Laying out the M&T joinery with my PM10 and 1172 jg on my PM66.

Ben

Reply With Quote

Reply With Quote

24" pm 2415 bandsaw (why do they come with such small fences?)

24" pm 2415 bandsaw (why do they come with such small fences?)