Today I needed to check whether the tenon shoulders of some curved stretchers were square .

This reminded me of a jig that Jeff Miller posted on his blog, which previewed a forthcoming article in Pop Wood magazine. This consists of a vise and a flush cutting saw (attached to the sole of a "plane").

Link: http://furnituremaking.com/wordpress/tenon-shoulders/

Jeff's jig:

I needed this today. However it occurred to me that I already had one .... as do many of you as well.

"I do?", you ask. Yep .. it's your Moxon dovetail vise.

As long as the chop is aligned with the rear of the vise and has some width for regiistration, then you are good to go.

Line up the shoulder you know ...

Use a flush cutting saw to cut the opposing shoulder. This will be square with the first shoulder ...

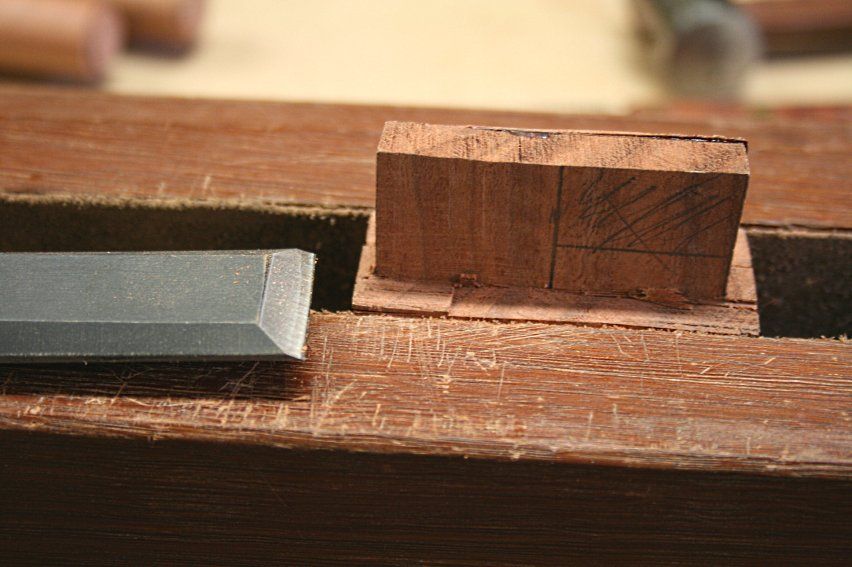

You can use a paring chisel if you only need to trim a little from an existing shoulder ...

Done ...

Regards from Perth

Derek

Reply With Quote

Reply With Quote