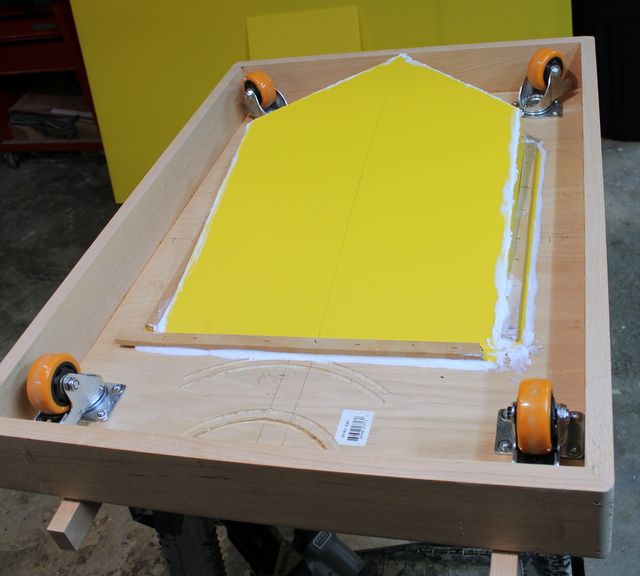

I have an early Unisaw that I use frequently for My Finish Carpentry/Built ins business. I needed a better way to collect dust, without cutting into the sheet metal.

Here's how I did it.John Phone 155.jpgJohn Phone 156.jpgJohn Phone 226.jpgJohn Phone 227.jpgJohn Phone 228.jpg

The boot that comes off the blade guard/collector is off my wife spare tire carrier (2004 trailblazer ), it somehow fit perfectly.

Reply With Quote

Reply With Quote