I am reposting some of the information from before as it is added to related data.

There have been disagreements about the shape of the chipbreaker here. I favour the newer LN and LV chipbreakers over the thin Stanley pressed metal version. My criticism of the Stanley type is simply that the ones I have are easily flexed, and difficult to set accurately without moving. Others are now arguing that the rounded front is critical to set up (for example, Warren says so based on historical information). It is an interesting situation, and I am open to dissuasion, but at this time I dispute this being the case. I will offer some testing below. Perhaps someone else can do the same. Feel free to pick holes in what I have done - it is all in the interest of better understanding.

Two years ago I argued the case against the Stanley chipbreaker here:

http://www.inthewoodshop.com/ToolRev...ipbreaker.html Granted, this was not directed at the rounded front from an angle perspective, but from the ease of setting the chipbreaker.

The front angle of the Stanley is around 45 degrees. The new LN and LV chipbreakers are 30 degrees, which is too low to use as is, and a secondary bevel must be added. I added these at 50 degrees. The leading edge is about 1/16" (around 1mm) high. That has been a focus for discussion here as well.

Recently I compared a new LN chipbreaker which I rounded ala Stanley/vintage woodies with a straight/secondary bevel LV chipbreaker. Planes were the LN #3 (45 degree frog) and LV Custom #4 (42 degree frog). The wood is Fiddleback Marri, a

very interlocked hardwood that would tearout just looking at it!

This is what I got from the LN (the straight shaving indicates that teh chipbreaker is effective) ...

The shape of the chipbreaker ..

And its positioning (about 0.2 - 0.3mm back) ..

Here is the LV. It should be at a slight disadvantage since the bed is slightly lower. Nevertheless, the shaving is the same ...

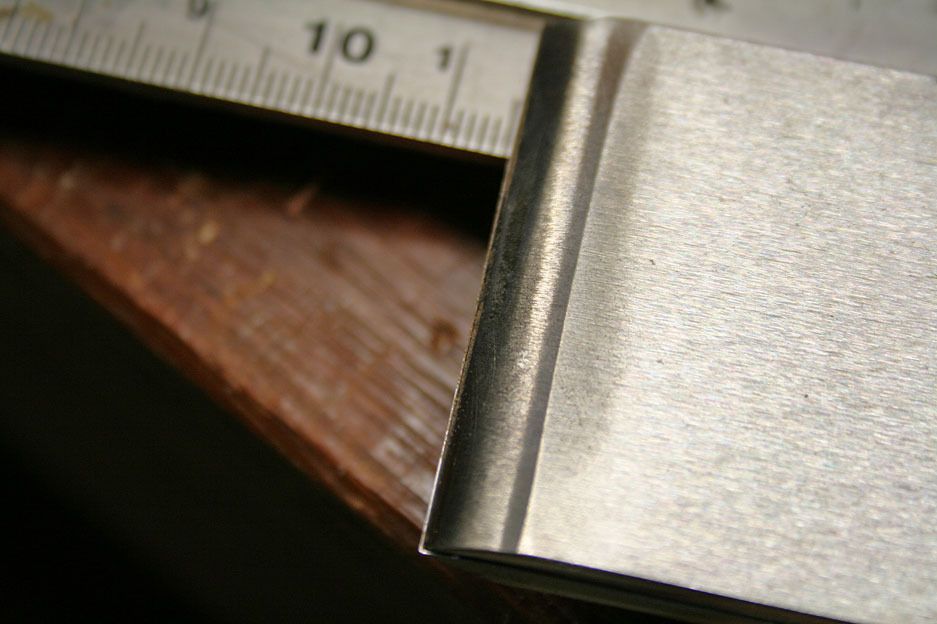

The shape of the chipbreaker ..

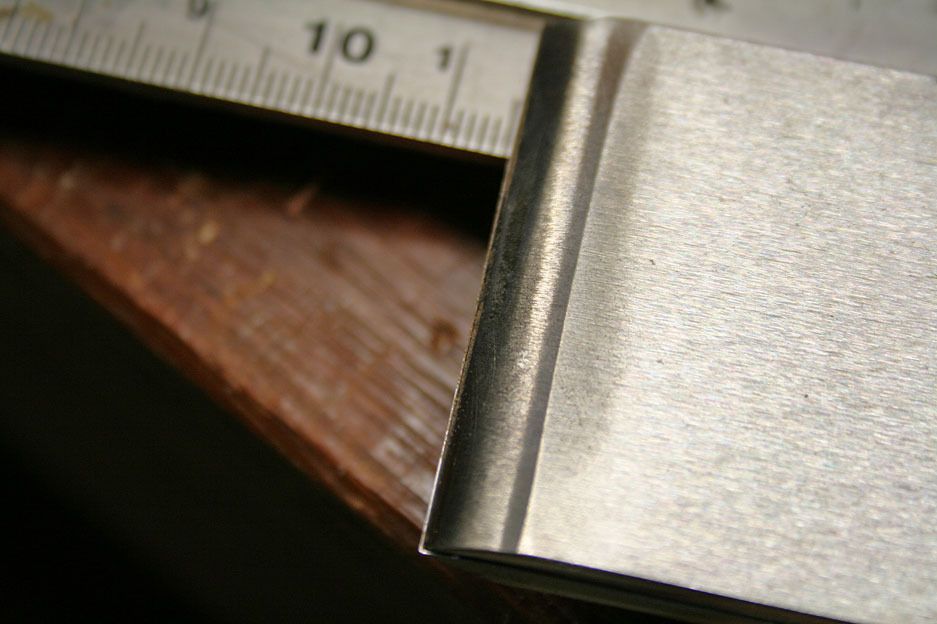

The positioning of the chipbreaker ..

Conclusion: same as

Regards from Perth

Dere?p-='k

Reply With Quote

Reply With Quote