I got a burn spot on my wide belt today and couldn't find that rubber thingy to clean the belt. Found that if I ran some lumber cross grain it would clean it right up.

I got a burn spot on my wide belt today and couldn't find that rubber thingy to clean the belt. Found that if I ran some lumber cross grain it would clean it right up.

That is interesting. How did you burn it. I was warned to not try sanding 3/4" wide pieces with mine, because it would burn a strip.

rarely happens on my wide belt. Thought it might be of more interest to those with drum sanders.

Mike,

I sand a lot of Western Maple on my 37" x 60" Lobo wide belt. I frequently burnt belts. Then I learned the following system would reduce the burn problem by about 90%.

I always start at the roughest grit necessary to get to the thickness desired.

First pass thru the sander is at a level that removes very little surface.

Second pass is a cutting pass, but I index the lumber at about 20 degrees off straight. I then adjust the cut to a new level, usually about 0.0025 to 0.0015 of cut. I then send the lumber thru again, this time 20 degrees off straight to the opposite direction. Then, without adjusting the cut level, I send the wood thru straight. Some times I send it thru several time at the same setting.

I tend to start with a 50 grit on rough sawn lumber, or 120 grit on S4S lumber, progressing to a maximum of 180 grit. I use this same system with each grit. The finer the grit, the smaller the changes to the cut. Each machine and each different wood may benefit from a different sequence and amount of changes to the cutting/sanding levels

I find the following results: [1] no burning of the lumber [or at least a great deal less] [2] better and quicker sanding, [3] significantly less burning of the belt and therefore, significantly longer belt life.

When I do get a burn on a belt, I attack the burn with my pressure washer. I usually can clean it off the burn with a few minutes of careful pressure washing.

Ira

Last edited by Ira Matheny; 02-13-2015 at 10:45 PM. Reason: more into

Mike, that is an interesting method. I have seen people use a crepe rubber eraser to clean a wide belt while it was running, but the risk of having the machine grab it and possibly a hand incline me more toward cleaning the belts off the machine. We use Renuzit, a scrub brush and water rinse to extend the belt life considerably unless the burns are severe in which case it's not worth the effort. We find the fine belts (we usually stop at 150-180) tend to develop some chatter from the process, so stick to cleaning the rougher belts used for stock removal.

Ira, are your figures correct? .002" seems like a very light cut indeed. With an 18 hp motor I would be taking off more like .015" at 50#.

There is a very useful discussion of wide belt sanding procedures here: http://surfprepsanding.com/2014/02/2...elt-sanding-2/

Are you guys using cloth belts?

JR

I do use cloth belts, but I've never thought of giving them a bath.

Sorry, the stuff we use is actually called Reuzit. I gather some people use Simple Green and other products in the same fashion.

If you're burning, you're removing too much material, moving too slowly, or the belt is shot. Depending on the feet per minute of the head, some machines are just hard on abrasives. The second head in my widebelt runs 180g and has a platen in it, it is moving at 4800 ft/min, and it's just plain hard on abrasives.

Kicking everything you can at an angle is important to for a few reasons.

1. Less load on the motor. Not a big deal if you are running a narrow pieces at random intervals, but when you have something that's 70% of the belt width hitting all at once, it creates a spike in the load.

2. Running long material at the same spot on the drum or platen, (or both), will create a hot spot. Heat kills belts. It will also make the belt more prone to loading which will cause more heat.

3. You're using more surface area of the belt, for more even wear of the abrasive.

I've pressure washed belts when I've loaded them up removing paint, but it's never gone well for me.

WOOPS. Got the decimal point in the wrong spot. I usually take 0.015 to 0.025 on each subsequent pass. Once I have is done, I end with several 0.002 passes. Give a good final product.

And yes. Western Maple is undoubtedly a major contributor to burning belts.

Indexing any wood to 15-20 degrees will help several issues. Belts run coolers. Evens the wear on the belt and the platen. Make the sanding marks much less pronounced when moving to next finer belt, therefore fewer passes required.

And grit matters a lot, of course. Taking too heavy a pass with too fine a grit is the #1 reason for burning, IME.

JR

Martin,

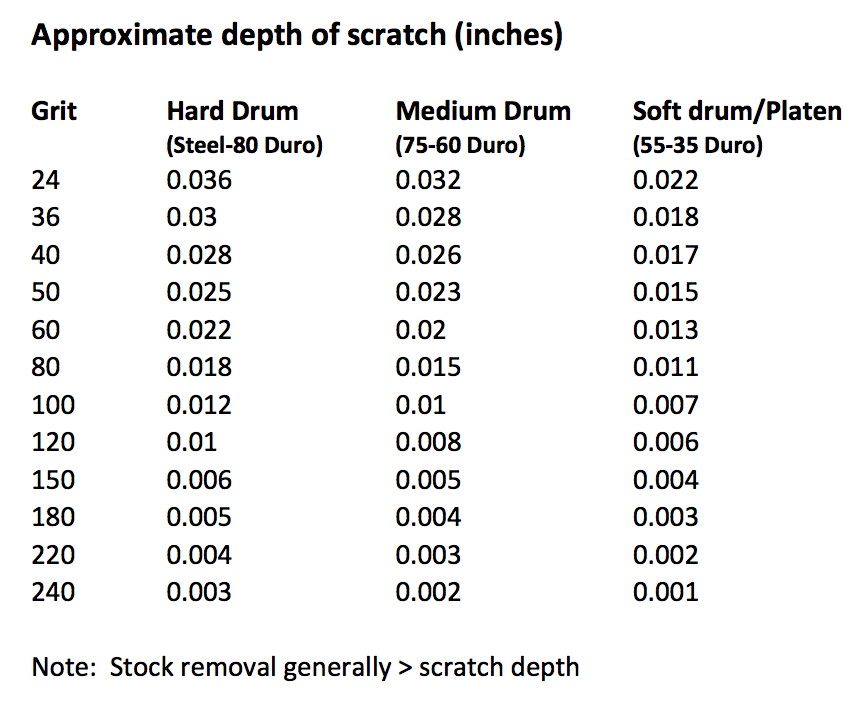

That must work for you, but it's very different from the way we run the single head Sandingmaster I am familiar with.If your figures are correct you are taking .024" with 120# and following with a.028" pass at 180#. That is far more than I would ever take with either grit- I max out at about .012" for 120# and .004" at 180#. Why are you removing so much material at the sander? We run an SCMI 20" planer with onboard grinder which gives very clean cuts with all but highly figured woods, and for general use I plane to .030" over final thickness, then sand off .010" on each face with 100# to make sure of removing the occasional snipe or tearout and .005" with 150" to remove the 100# scratches. Once milling or assembly defects are removed with a coarse belt there is no reason to do more than refine the scratch pattern with subsequent grits. There is a good table here http://surfprepsanding.com/2014/02/2...elt-sanding-2/giving maximum recommended cuts with various grits as well as the minimum cut to get down below the scratches from earlier grits. Not saying your method is wrong, but it differs a lot from the way I have learned to run our machine. How much power do you have to work with on each head? What sort of belts are you using, and how much life do you get from them?

You may all be aware of this, but I will throw it out there anyhow. On a Timesaver (not sure about others) There is a height adjustable bar across the front. You can adjust it so the board just fits under at the optimum sanding height, if the bed is raised too high which would result in too aggressive of a pass, the board wont fit. We reduced our burning problems to almost zero after we figured this out...